Description

Operational Areas

The ideal use for these cylinders is in the construction industry, for example, bridge repairs and constructions and in the building and maintenance of heavy structural works. The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.

Options

- T version, cylinder with integrated tilt saddle.

- F version, cylinder with mounting holes for fixing purposes at the bottom.

- N version, (optional starting from 50 t) cylinders with end of stroke ring nut.

This version is in compliance with ANSI B30.1.

- M version, cylinder with spring return.

This version is available for N – version cylinders up to 150 tons (i.e., CMG50N100).

Selection Chart

30 309 Tr 65 x6 2xM10 13 50 496 Tr 95 x6 Tr 85 x6 2xM12 15 Tr 130 x10 Tr 110 x10 2xM12 17 Tr 160 x10 Tr 130 x10 4xM12 17 Tr 190 x10 Tr 165 x10 4xM16 20

STROKE

EFFECTIVE

AREA

OIL VOLUME

MODEL

CLOSED HEIGHT

CLOSED HEIGHT

WITH INTEGRATED TILT SADDLE

Ø EXTERNAL

Ø PISTON

Ø ROD VERSION P

Ø ROD VERSION N

COUPLER HEIGHT

ØINTEGRATED TILT

SADDLE

ROD PROJECTION

ROD PROJECTION

WITH INTEGRATED TILT SADDLE

Ø PCD MUNTING

HOLES

MOUNTING HOLES

DEPTH

WEIGHT

* Nominal value, for precise capacity see kN

t* KN

mm

cm²

cm³

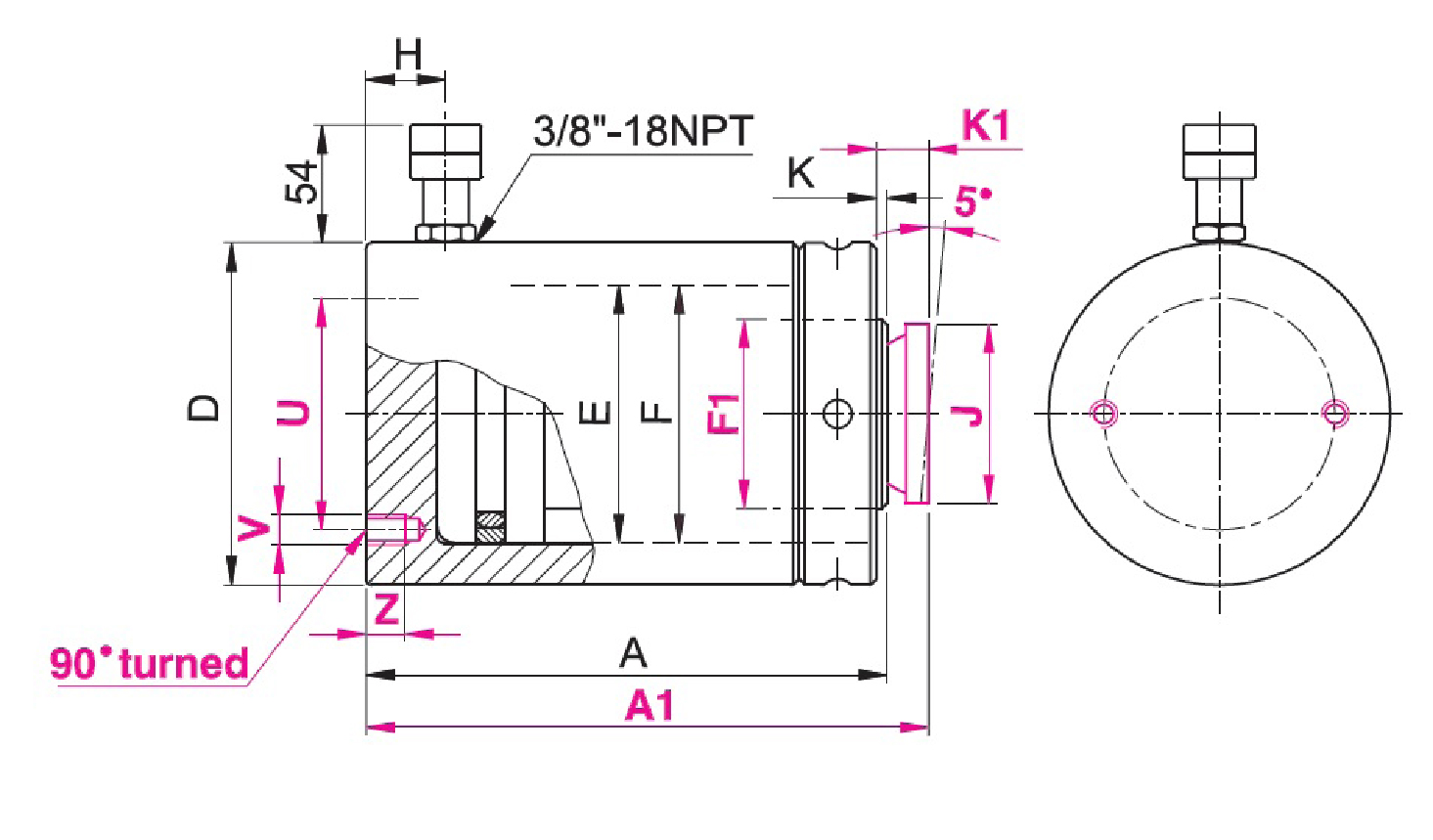

A

A1

D

E

F

F1

H

J

K

K1

U

V / Z

kg

100

44.1

442

CGG30N100

189

193

102

75

–

19

53

1

5

65

11

50

70.9

355

CGG50P50

158

163

127

95

22

68

1

6

95

15.5

100

709

CGG50P100

208

213

20

150

1063

CGG50P150

258

263

25

100

929

100

132.7

1327

CGG100P100

236

243

175

130

22

88

2

9

130

44

150

1991

CGG100P150

286

293

53.5

150 1407

25

201

503

CGG150P25

184

193

213

160

30

118

3

12

130

51

50

1005

CGG150P50

209

218

58

100

2011

CGG150P100

259

268

72

150

3016

CGG150P150

309

318

86

200

4021

CGG150P200

359

368

100

250

5026

CGG150P250

409

418

114

200 1984

25

283.4

709

CGG200P25

205

214

252

190

32

148

3

12

140

80

50

1418

CGG200P50

230

239

90

100

2835

CGG200P100

280

289

109

150

4253

CGG200P150

330

339

129

200

5670

CGG200P200

380

389

148

250

7088

CGG200P250

430

439

168

300

8506

CGG200P300

480

489

187

Selection Chart

250 2424 Tr 210 x10 Tr 175 x10 4xM16 20 300 2908 Tr 230 x10 Tr 195 x10 4xM16 20 350 3436 Tr 250 x10 Tr 215 x10 4xM16 20

PUSHING FORCE

STROKE

EFFECTIVE AREA

OIL VOLUME

MODEL

CLOSED HEIGHT

CLOSED HEIGH WITH INTEGRATED TILT SADDLE

Ø EXTERNAL

Ø PISTON

Ø ROD VERSION P

Ø ROD VERSION N

COUPLER HEIGHT

Ø INTEGRATED TILT SADDLE

ROD PROJECTION

ROD PROJECTION WITH INTEGRATED TILT SADDLE

Ø PCD MOUNTING HOLES

MOUNTING HOLES DEPTH

WEIGHT

t*

mm

cm²

cm3

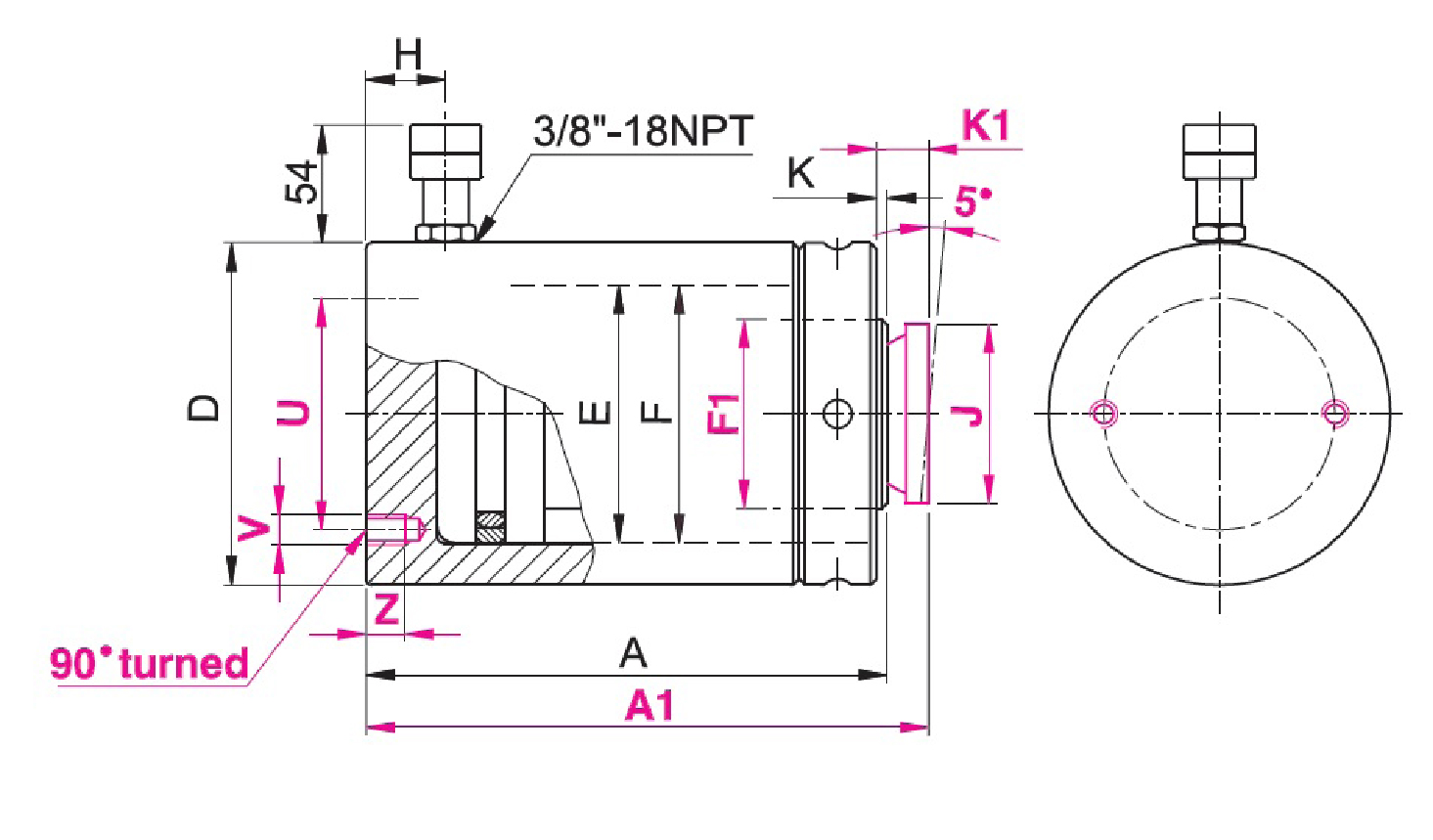

A

A1

D

E

F

F1

H

J

K

K1

U

V / Z

kg

25

866

CGG250P25

224

233

280

210

34

158

3

12

150

108

50

1732

CGG250P50

249

258

120

100

346.3

3464

CGG250P100

299

308

144

150

5195

CGG250P150

349

358

168

200

6927

CGG250P200

399

408

192

250

8659

CGG250P250

449

458

217

300

10391

CGG250P300

499

508

241

25

1039

CGG300P25

240

249

305

230

38

158

3

12

170

137

50

2077

CGG300P50

265

274

152

100

415.4

4155

CGG300P100

315

324

180

150

6232

CGG300P150

365

374

209

200

8310

CGG300P200

415

424

238

250

10387

CGG300P250

465

474

266

300

12464

CGG300P300

515

524

295

25

1227

CGG350P25

250

262

332

250

42

196

3

15

200

170

50

2454

CGG350P50

275

287

187

100

4909.6

4909

CGG350P100

325

337

221

150

7363

CGG350P150

375

387

255

200

9818

CGG350P200

425

437

289

250

12272

CGG350P250

475

487

322

300

14726

CGG350P300

525

537

356

Selection Chart

PUSHING FORCE

STROKE

EFFECTIVE AREA

OIL VOLUME

MODEL

CLOSED HEIGTH

CLOSED HEIGTH WITH INTEGRATED TILT SADDLE

Ø EXTERNA

Ø PISTON

Ø ROD VERSION P

Ø ROD VERSION N

COUPLER HEIGHT

Ø INTEGRATED TILT SADDLE

ROD PROJECTION

ROD PROJECTION WITH INTEGRATED TILT SADDLE

Ø PCD MOUNTING HOLES

MOUNTING HOLES DEPTH

WEIGHT

Precise capacity see kN

t* kN

mm

cm²

cm3

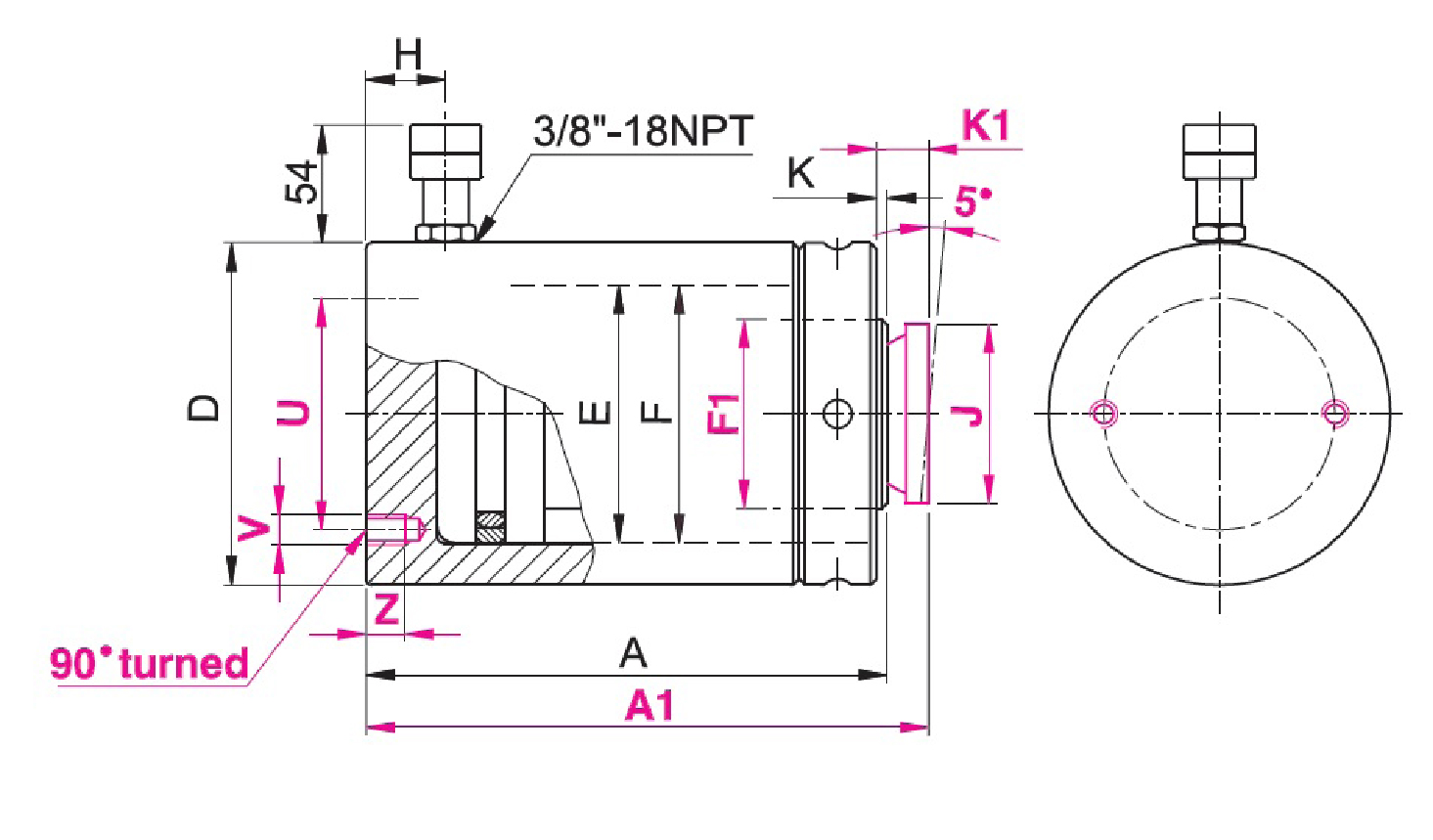

A

A1

D

E

F

F1

H

J

K

K1

U

V / Z

kg

400 4008

25

572.6

1431

CGG400P25

260

272

356

270

Tr

270 x10

Tr

235 x10

42

196

3

15

230

4xM16 20

203

50

2863

CGG400P50

285

297

222

100

5726

CGG400P100

335

347

261

150

8588

CGG400P150

385

397

300

200

11451

CGG400P200

435

447

298

250

14314

CGG400P250

485

497

379

300

17177

CGG400P300

535

547

418

500 4948

25

706.9

1767

CGG500P25

275

287

396

300

Tr 300 x10

Tr 260 x 10

50

196

3

15

250

4xM16 20

265

50

3534

CGG500P50

300

312

290

100

7069

CGG500P100

350

362

338

150

10603

CGG500P150

400

412

386

200

14137

CGG500P200

450

462

435

250

17651

CGG500P250

500

512

483

300

21206

CGG500P300

550

562

53

Selection Chart

| MODEL | FOR USE WITH | a | b | j | z | kg |

| ZTT30 | CGG30N100 | 19 | 1 | 53 | M5 | 0.3 |

| ZTT50 | CGG50 # # # # | 25 | 68 | M8 | 0.9 | |

| ZTT100 | CGG100 # # # # | 34 | 2 | 88 | M10 | 1.7 |

| ZTT150 | CGG150 # # # # | 45 | 3 | 118 | 3.4 | |

| ZTT200 | CGG200 # # # # | 54 | 3 | 148 | 7 | |

| ZTT250 | CGG250 # # # # | 58 | 158 | 9.5 | ||

| ZTT300 | CGG300 # # # # | 11.3 | ||||

| ZTT350 | CGG350 # # # # | 71 | 196 | M12 | 18 | |

| ZTT400 | CGG400 # # # # | 20.7 | ||||

| ZTT500 | CGG500 # # # # | 23.8 |