Description

Operational Areas

These hydraulic cylinders are extremely solid and are recommended for the lifting, lowering, and sustaining of a heavy load. They are carried out specifically strong in order to be useful in applications that require very heavy loads to be lifted. The anti-corrosion treatment applied to these cylinders makes them suitable for use in harsh and adverse environments.

Options

-

T version: Cylinder with integrated tilt saddle.

-

F version: Cylinder with base mounting holes for fixing purposes.

-

N version: (Optional starting from 50 t) cylinders with end of stroke ring nut.

This version is in compliance with ANSI B30.1.

Accessories

- ZTT tilt saddle reduces the effects of any possible off-centred load.

Whenever P version cylinders are being used, the operator must always be in a position to observe when the coloured end of the stroke section of the rod appears.

Selection Chart

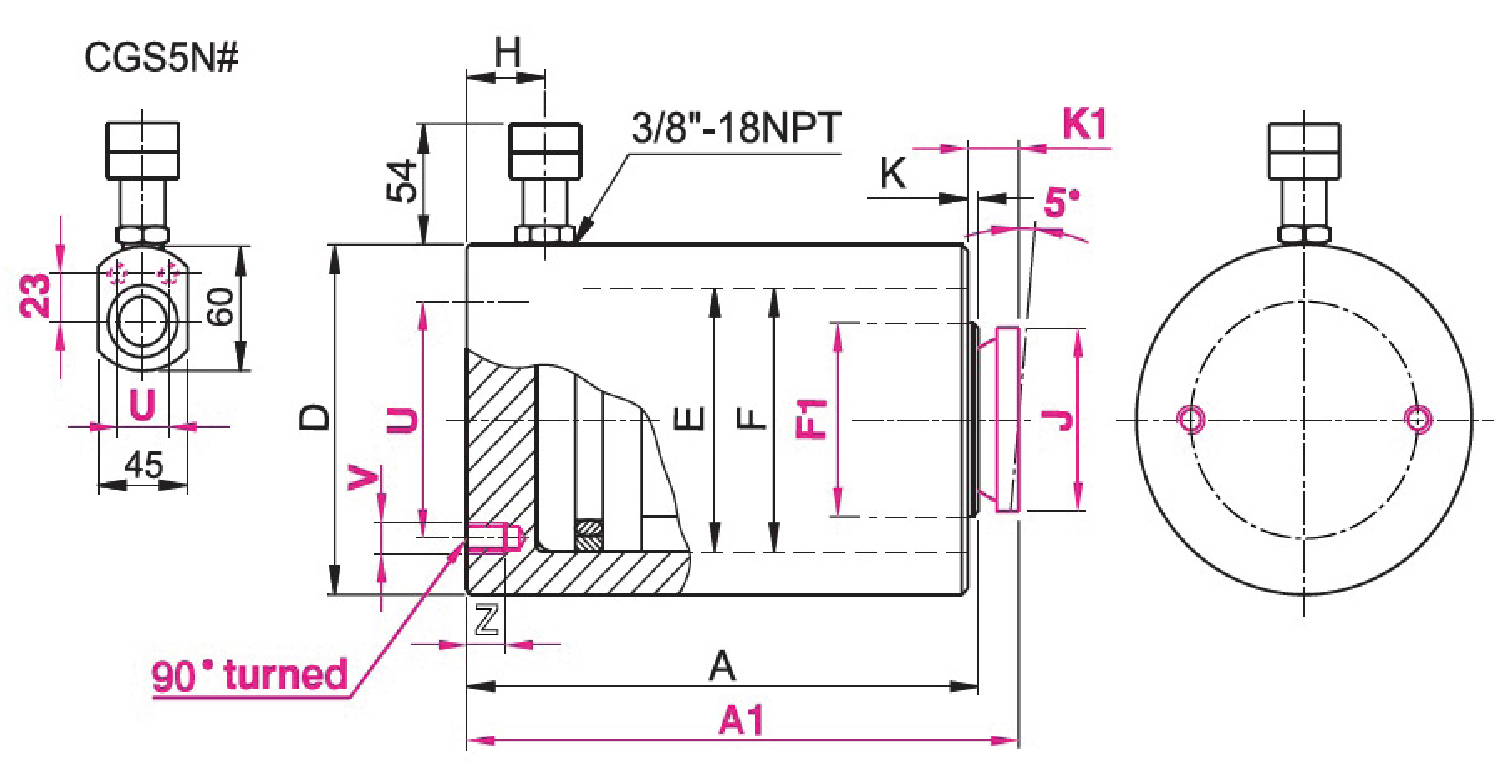

| PUSHING FORCE | STROKE | EFFECTIVE AREA | OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH INTEGRATED TILT SADDLE | Ø EXTERNAL | Ø PISTON | Ø ROD VERSION P | Ø ROD VERSION N | COUPLER HEIGHT | ØINTEGRATED TILT SADDLE | ROD PROJECTION | ROD PROJECTION WITH INTEGRATED TILT SADDLE | Ø PCD MUNTING HOLES | MOUNTING HOLES DEPTH | WEIGHT | *Nominal value, for precise capacity see kN |

| t* KN | mm | cm² | cm³ | A | A1 | D | E | F | F1 | H | J | K | K1 | U | V / Z | kg | ||

|

5 49.5 |

15 | 7.1 | 11 | CGS5N15 | 45 | – | 60/45 | 30 | – | 24 | 19 | – | 1 | – | 30 |

2xM5 |

1 | |

| 50 | 35 | CGS5N50 | 80 | 1.6 | ||||||||||||||

| 80 | 56 | CGS5N80 | 120 | 2.4 | ||||||||||||||

|

10 111 |

25 | 15.9 | 40 | CGS10N25 | 72 | 75 | 75 | 45 | – | 35 | 19 | 34 | 1 | 4 | 25 |

2xM8 |

2.8 | |

| 50 | 80 | CGS10N50 | 97 | 100 | 3.6 | |||||||||||||

|

20 198 |

25 | 28.3 | 71 | CGS20N25 | 75 | 80 | 88 | 60 | – | 45 | 19 | 43 | 1 | 6 | 60 |

2xM10 |

3.7 | |

| 50 | 141 | CGS20N50 | 100 | 105 | 4.7 | |||||||||||||

| 100 | 283 | CGS20N100 | 150 | 155 | 6.6 | |||||||||||||

|

30 309 |

25 | 44.1 | 110 | CGS30N25 | 86 | 90 | 102 | 75 | – | 55 | 19 | 53 | 1 | 5 | 65 |

2xM10 |

5.5 | |

| 50 | 221 | CGS30N50 | 111 | 115 | 6.7 | |||||||||||||

| 100 | 442 | CGS30N100 | 161 | 165 | 9.1 | |||||||||||||

|

50 496 |

50 | 70.9 | 354 | CGS50P50 | 122 | 127 | 127 | 95 | 95 | 80 | 22 | 68 | 1 | 6 | 95 |

2xM12 |

12 | |

| 100 | 709 | CGS50P100 | 172 | 177 | 17 | |||||||||||||

| 150 | 1063 | CGS50P150 | 222 | 227 | 22 | |||||||||||||

|

100 929 |

50 | 132.7 | 664 | CGS100P50 | 141 | 148 | 175 | 130 | 130 | 100 | 22 | 88 | 2 | 9 | 130 |

2xM12 |

27 | |

| 100 | 1327 | CGS100P100 | 191 | 198 | 36 | |||||||||||||

| 150 | 1991 | CGS100P150 | 241 | 248 | 46 | |||||||||||||

|

150 1407 |

25 | 201 | 503 | CGS150P25 | 137 | 146 | 213 | 160 | 160 | 120 | 30 | 118 | 3 | 12 | 130 |

4xM12 |

38 | |

| 50 | 1005 | CGS150P50 | 162 | 171 | 45 | |||||||||||||

| 100 | 2011 | CGS150P100 | 212 | 221 | 59 | |||||||||||||

| 150 | 3016 | CGS150P150 | 262 | 271 | 73 | |||||||||||||

| 200 | 4021 | CGS150P200 | 312 | 321 | 87 | |||||||||||||

| 250 | 5026 | CGS150P250 | 362 | 371 | 101 |

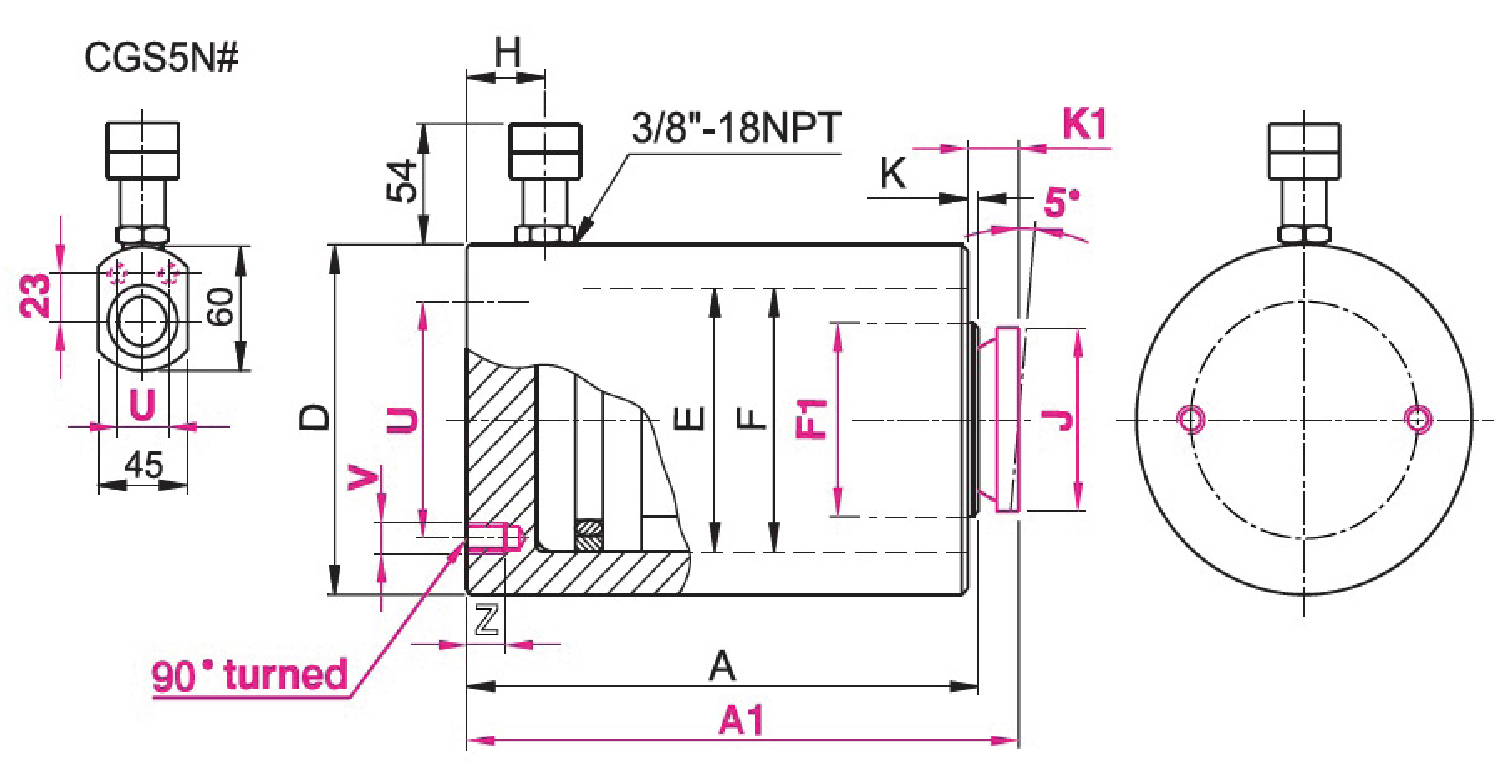

Selection Chart

| PUSHING FORCE | STROKE | EFFECTIVE AREA | OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH INTEGRATED TILT SADDLE | Ø EXTERNAL | Ø PISTON | Ø ROD VERSION P | Ø ROD VERSION N | COUPLER HEIGHT | ØINTEGRATED TILT SADDLE | ROD PROJECTION | ROD PROJECTION WIDTH INTEGRATED TILT SADDLE | Ø PCD MOUNTING HOLES | MOUNTING HOLES DEPTH | WEIGHT | * Nominal value, see kN for the exact force |

| t* kN | mm | cm² | cm3 | A | A1 | D | E | F | F1 | H | J | K | K1 | U | V / Z | kg | ||

|

200 |

25 | 283.4 | 709 | CGS200P25 | 151 | 160 | 252 | 190 | 190 | 150 | 32 | 148 | 3 | 12 | 140 |

4xM16 |

59 | |

| 50 | 1418 | CGS200P50 | 176 | 185 | 69 | |||||||||||||

| 100 | 2835 | CGS200P100 | 226 | 235 | 88 | |||||||||||||

| 150 | 4253 | CGS200P150 | 276 | 285 | 108 | |||||||||||||

| 200 | 5670 | CGS200P200 | 326 | 335 | 127 | |||||||||||||

| 250 | 7088 | CGS200P250 | 376 | 385 | 147 | |||||||||||||

| 300 | 8506 | CGS200P300 | 426 | 435 | 167 | |||||||||||||

|

250 |

25 | 346.3 | 866 | CGS250P25 | 167 | 176 | 280 | 210 | 210 | 170 | 34 | 158 | 3 | 12 | 150 |

4xM16 |

81 | |

| 50 | 1732 | CGS250P50 | 192 | 201 | 93 | |||||||||||||

| 100 | 3464 | CGS250P100 | 242 | 251 | 117 | |||||||||||||

| 150 | 5195 | CGS250P150 | 292 | 301 | 141 | |||||||||||||

| 200 | 6927 | CGS200P200 | 342 | 351 | 165 | |||||||||||||

| 250 | 8659 | CGS250P250 | 392 | 401 | 189 | |||||||||||||

| 300 | 10391 | CGS250P300 | 442 | 451 | 213 | |||||||||||||

|

300 |

25 | 415.4 | 1039 | CGS300P25 | 173 | 182 | 305 | 230 | 230 | 190 | 38 | 158 | 3 | 12 | 170 |

4xM16 |

99 | |

| 50 | 2077 | CGS300P50 | 198 | 207 | 113 | |||||||||||||

| 100 | 4155 | CGS300P100 | 248 | 257 | 142 | |||||||||||||

| 150 | 6232 | CGS300P150 | 298 | 307 | 171 | |||||||||||||

| 200 | 8310 | CGS300P200 | 348 | 357 | 199 | |||||||||||||

| 250 | 10387 | CGS300P250 | 398 | 407 | 228 | |||||||||||||

| 300 | 12464 | CGS300P300 | 448 | 457 | 257 |

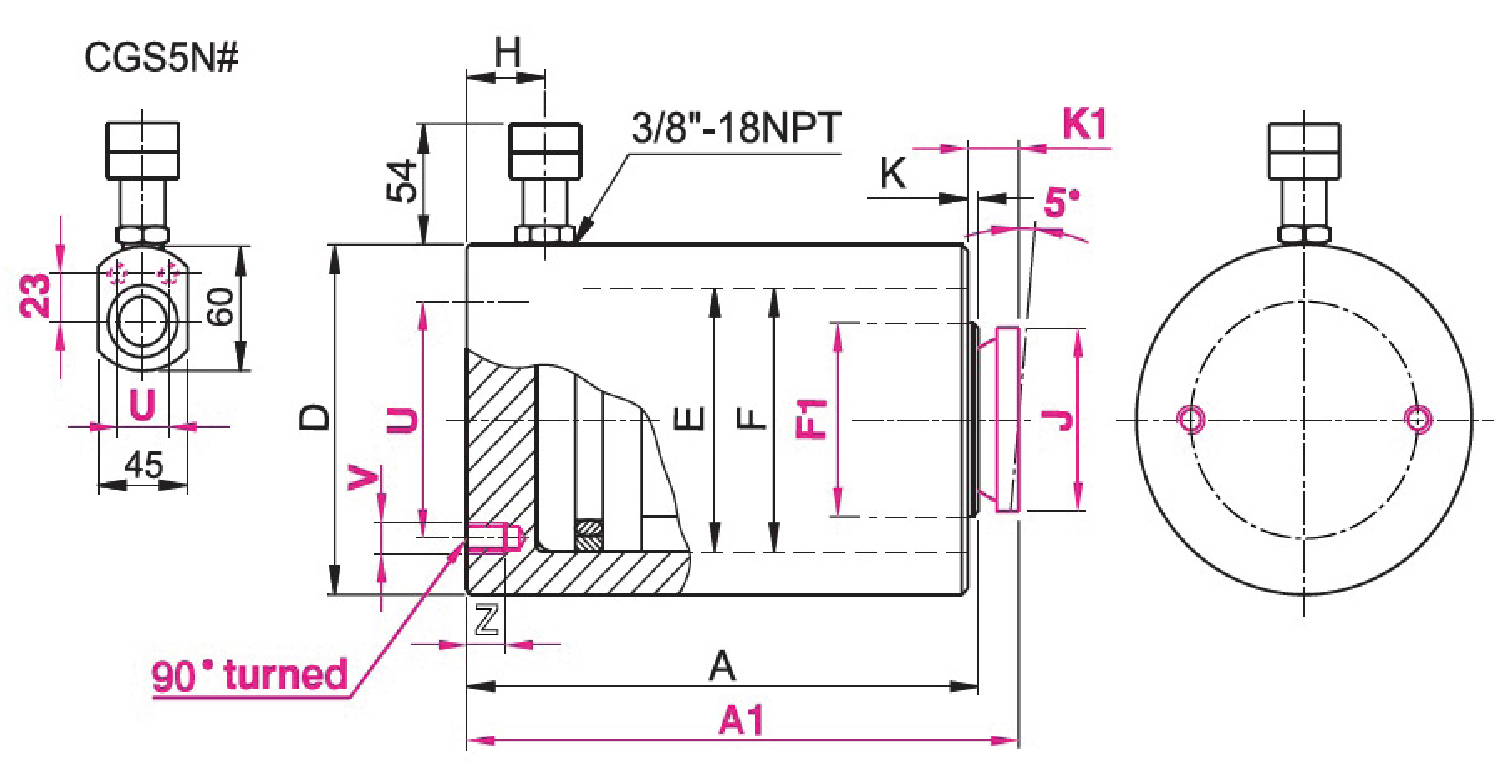

Selection Chart

| PUSHING FORCE | STROKE | EFFECTIVE AREA | OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH INTEGRATED TILT SADDLE | Ø EXTERNAL | Ø PISTON | Ø ROD VERSION P | Ø ROD VERSION N | COUPLER HEIGHT | Ø INTEGRATED TILT SADDLE | ROD PROJECTION | ROD PROJECTION WITH INTEGRATED TILT SADDLE | Ø PCD MOUNTING HOLES | MOUNTING HOLES DEPTH | WEIGHT | * Nominal value, see kN for the exact force |

| t* kN | mm | cm² | cm3 | A (mm) | A1 (mm) | D (mm) | E (mm) | F (mm) | F1 (mm) | H (mm) | J (mm) | K (mm) | K1 (mm) | U (mm) | V / Z (mm) | KG | ||

| 350 3436 | 25 | 490.9 | 1227 | CGS350P25 | 180 | 192 | 332 | 250 | 250 | 210 | 39 | 196 | 3 | 15 | 200 |

4xM16 |

122 | |

| 50 | 2454 | CGS350P50 | 205 | 217 | 139 | |||||||||||||

| 100 | 4909 | CGS350P100 | 255 | 267 | 173 | |||||||||||||

| 150 | 7363 | CGS350P150 | 305 | 317 | 207 | |||||||||||||

| 200 | 9817 | CGS300P200 | 355 | 367 | 241 | |||||||||||||

| 250 | 12272 | CGS350P250 | 405 | 417 | 275 | |||||||||||||

| 300 | 14726 | CGS350P300 | 455 | 467 | 309 | |||||||||||||

| 400 4008 | 25 | 572.6 | 1431 | CGS400P25 | 187 | 199 | 356 | 270 | 270 | 230 | 42 | 196 | 3 | 15 | 230 |

4xM16 |

146 | |

| 50 | 2863 | CGS400P50 | 212 | 224 | 165 | |||||||||||||

| 100 | 5726 | CGS400P100 | 262 | 274 | 204 | |||||||||||||

| 150 | 8588 | CGS400P150 | 312 | 324 | 244 | |||||||||||||

| 200 | 11451 | CGS400P200 | 362 | 374 | 283 | |||||||||||||

| 250 | 14314 | CGS400P250 | 412 | 424 | 322 | |||||||||||||

| 300 | 17177 | CGS400P300 | 462 | 474 | 361 | |||||||||||||

| 500 4948 | 25 | 706.9 | 1767 | CGS500P25 | 195 | 207 | 396 | 300 | 300 | 250 | 50 | 196 | 3 | 15 | 250 |

4xM16 |

188 | |

| 50 | 3534 | CGS500P50 | 220 | 232 | 212 | |||||||||||||

| 100 | 7069 | CGS500P100 | 270 | 282 | 261 | |||||||||||||

| 150 | 10603 | CGS500P150 | 320 | 332 | 309 | |||||||||||||

| 200 | 14137 | CGS500P200 | 370 | 382 | 357 | |||||||||||||

| 250 | 17651 | CGS500P250 | 420 | 432 | 406 | |||||||||||||

| 300 | 21206 | CGS500P300 | 470 | 482 | 454 |