Description

Operational Areas

These cylinders can be operated in any position and are extremely versatile and suitable for different applications, including industrial works, steel structural works, presses, and special applications. The nitride treatment gives these cylinders an excellent resistance to corrosion and makes them particularly suitable to operate in the open air or in aggressive environments.

Accessories

- ZTT tilt saddle reduces the effects of any possible off-centred load.

- Base plates. ZAB

- Clevis eyes. ZAR and ZAE

Standard

- Base mounting holes.

- Pushing saddle prevents any risk of rod deformation.

To operate with these cylinders, the MD power units are particularly suitable.

Selection Chart

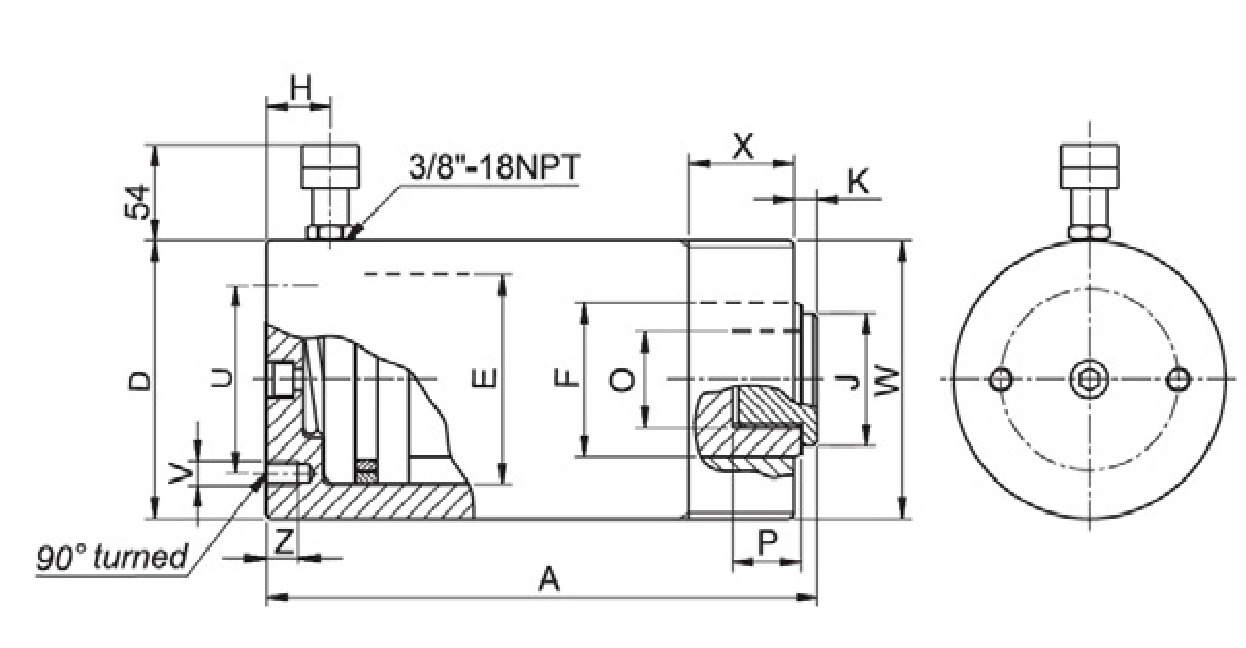

| PUSHING FORCE | STROKE | EFFECTIVE AREA | OIL VOLUME | MODEL | CLOSED HEIGHT | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLER HEIGHT | Ø HOLLOW SADDLE | ROD PROJECTION | ROD INTERNAL THREAD | ROD THREAD DEPTH | Ø IPCD MOUNTING HOLES | MOUNTING HOLES DEPTH | COLLAR THREAD COLLAR LENGTH | WEIGHT |

| t* kN | mm | cm² | cm3 | A (mm) | D (mm) | E (mm) | F (mm) | H (mm) | J (mm) | K (mm) | O (mm) | P (mm) | U (mm) | V / Z (mm) | W / X (mm) | Kg | |

| 5 49.5 | 25 | 7.1 | 18 | CMI5N25 | 92 | 40 | 30 | 25 | 19 | 24.5 | 2 | M16x1.5 | 14 | 25 | 2xM6 10 | M40x1.5 28 | 1.1 |

| 50 | 35 | CMI5N50 | 117 | 1.3 | |||||||||||||

| 75 | 53 | CMI5N75 | 142 | 1.5 | |||||||||||||

| 125 | 88 | CMI5N125 | 202 | 1.9 | |||||||||||||

| 175 | 124 | CMI5N175 | 252 | 2.3 | |||||||||||||

| 225 | 159 | CMI5N225 | 302 | 2.7 | |||||||||||||

| 10 111 | 25 | 15.9 | 40 | CMI10N25 | 83 | 60 | 45 | 35 | 19 | 33 | 1 | - | - | 39 | 2xM8 12 | M60x1.5 28 | 2 |

| 50 | 80 | CMI10N50 | 120 | 34 | 5 | M24x2 | 15 | 2.6 | |||||||||

| 100 | 159 | CMI10N100 | 170 | 3.5 | |||||||||||||

| 150 | 238 | CMI10N150 | 245 | 4.7 | |||||||||||||

| 200 | 318 | CMI10N200 | 295 | 5.6 | |||||||||||||

| 250 | 398 | CMI10N250 | 345 | 6.5 | |||||||||||||

| 300 | 477 | CMI10N300 | 408 | 65 | 35 | 9.3 | |||||||||||

| 350 | 557 | CMI10N350 | 458 | 10 | |||||||||||||

| 25 232 | 25 | 33.4 | 83 | CMI25N25 | 119 | 85 | 65 | 55 | 19 | 53 | 9 | M32x2 | 16 | 58 | 2xM10 14 | M85x2 40 | 4.6 |

| 50 | 166 | CMI25N50 | 144 | 5.3 | |||||||||||||

| 100 | 332 | CMI25N100 | 214 | 7.5 | |||||||||||||

| 150 | 498 | CMI25N150 | 264 | 8.8 | |||||||||||||

| 200 | 664 | CMI25N200 | 314 | 10.2 | |||||||||||||

| 250 | 830 | CMI25N250 | 364 | 11.6 | |||||||||||||

| 300 | 996 | CMI25N300 | 414 | 13 | |||||||||||||

| 350 | 1161 | CMI25N350 | 464 | 15 | |||||||||||||

| 30 309 | 210 | 44.1 | 928 | CMI30N210 | 386 | 102 | 75 | 55 | 47 | 53 | 9 | M32x2 | 16 | – | – | 3 5/16” -12 49 | 18.4 |

| 50 496 | 50 | 70.9 | 354 | CMI50N50 | 164 | 127 | 95 | 80 | 25 | 65 | 4 | M16 | 12 | 95 | 2xM12 18 | M125x2 40 | 14.2 |

| 100 | 709 | CMI50N100 | 214 | 17.4 | |||||||||||||

| 150 | 1063 | CMI50N150 | 264 | 20.8 | |||||||||||||

| 325 | 2304 | CMI50N325 | 439 | 32.6 | |||||||||||||

| 100 929 | 100 | 132.7 | 1327 | CMI100N100 | 246 | 175 | 130 | 100 | 26 | 85 | 4 | M16 | 17 | 140 | 2xM12 18 | M168x2 51 | 39.6 |

| 150 | 1991 | CMI100N150 | 296 | 46 |

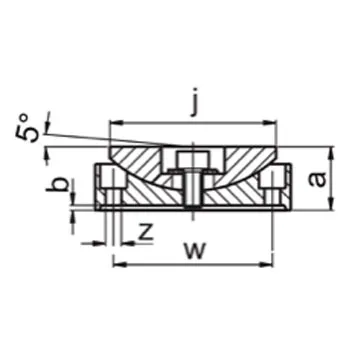

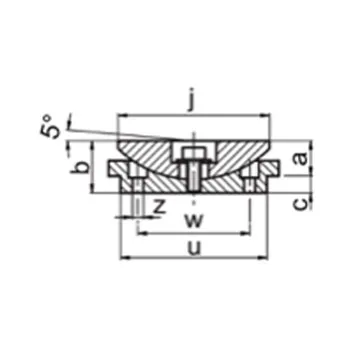

Accessories ZTT Tilt Saddle

| MODELL | FOR USE WITH | amm | bmm | cmm | jmm | umm | zmm | wmm | kg | |

|

ZTT10 | CMI10N25 | 16 | 1 | – | 34 | – | 5.5 | 24 | 0.1 |

|

ZTT11 | CMI10N # # # | 9 | 21 | 12 | 34 | M24x2 | – | – | 0.1 |

| ZTT11W | CMI10W # # # | 9 | 21 | 12 | 34 | 1’’ – 8 | – | – | 0.1 | |

| ZTT31 | CMI25N # # # | 16 | 30 | 14 | 53 | M32x2 | – | – | 0.3 | |

| ZTT31W | CMI25W # # # | 16 | 30 | 14 | 53 | 1 ½’’ – 16 | – | – | 0.3 | |

|

ZTT51 | CMI50 # # # # | 18 | 26 | 8 | 68 | 65 | 5.5 | 45 | 0.8 |

| ZTT101 | CMI100 # # # # | 22 | 32 | 10 | 88 | 85 | 6.5 | 65 | 1.6 |

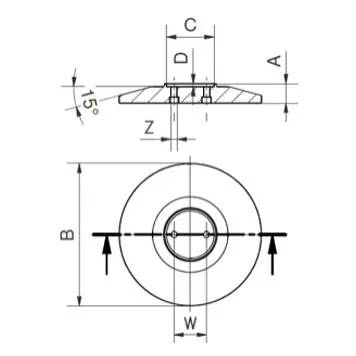

Accessories ZAB Base Plates

| MODEL | FOR USE WITH | amm | bmm | cmm | dmm | zmm | wmm | kg | |

|

ZAB5 | CMI5N###CMI5W### | 35 | 215 | 40 | 5 | 7 | 25 | 6.4 |

| ZAB10 | CMI10N # # #CMI10W### | 35 | 235 | 60 | 5 | 9 | 39 | 7.9 | |

| ZAB25 | CMI25N###CMI25W### | 35 | 255 | 85 | 5 | 11 | 58 | 9.5 |

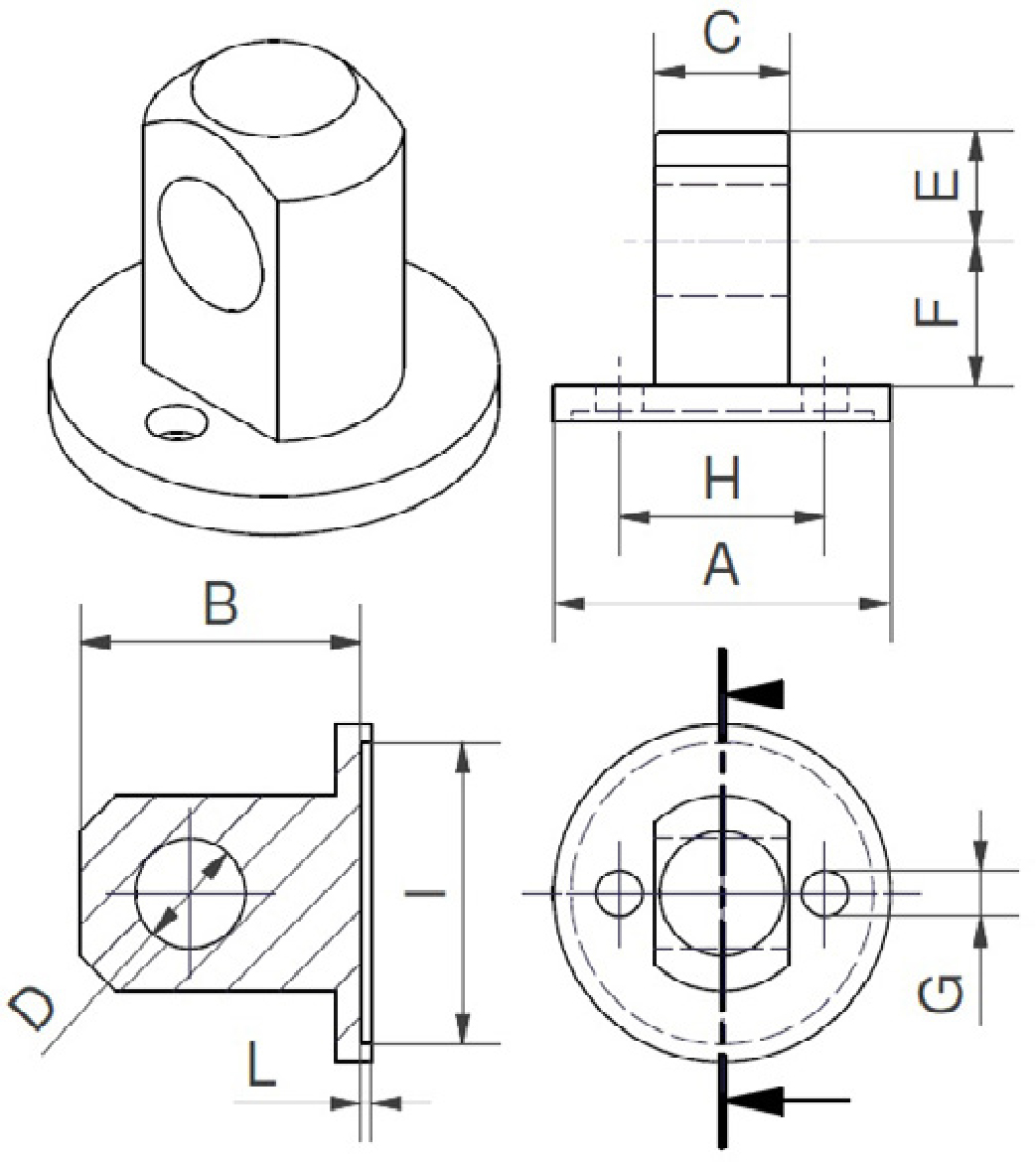

Accessories ZAE#M Plunger Clevis Eyes

| MODEL | FOR USE WITH | Amm | Bmm | Cmm | Dmm | Emm | Fmm | Gmm | Hmm | kg |

| ZAE5M | CMI5N # # # | Ø28 | 55 | 14 | Ø16 | 16 | 19 | 10 | M16 x2 | 0.15 |

| ZAE10M | CMI10N # # # | Ø42 | 73 | 25 | Ø22 | 25 | 28 | 12 | M24 x2 | 0.45 |

| ZAE25M | CMI25N # # # | Ø57 | 85.5 | 38 | Ø31 | 31 | 35 | 14.5 | M32 x2 | 1 |

| ZAE5MW | CMI5W # # # | Ø28 | 55 | 14 | Ø16 | 16 | 19 | 10 | 3/4’’ – 16 | 0.15 |

| ZAE10MW | CMI10W # # # | Ø42 | 73 | 25 | Ø22 | 25 | 28 | 12 | 1’’ – 8 | 0.45 |

| ZAE25MW | CMI25W # # # | Ø57 | 85.5 | 38 | Ø31 | 31 | 35 | 14.5 | 1 ½’’ – 16 | 1 |

Accessories Zar Base Clevis Eyes

| MODEL | FOR USE WITH | Amm | Bmm | Cmm | Dmm | Emm | Fmm | Gmm | Hmm | Imm | Lmm | kg |

| ZAR5 | CMI5N### | Ø45 | 47 | 14 | Ø16 | 16 | 25 | Ø7 | Ø25 | Ø40 | 4 | 0.2 |

| ZAR10 | CMI10N### | Ø65 | 66 | 25 | Ø22 | 25 | 35 | Ø8,5 | Ø39 | Ø60 | 4 | 0.6 |

| ZAR25 | CMI25N### | Ø95 | 79 | 38 | Ø31 | 31 | 41 | Ø13 | Ø58 | Ø85 | 3 | 1.3 |

| ZAR5W | CMI5W### | Ø45 | 47 | 14 | Ø16 | 16 | 25 | Ø7 | Ø25 | Ø38 | 4 | 0.2 |

| ZAR10W | CMI10W### | Ø65 | 66 | 25 | Ø22 | 25 | 35 | Ø8,5 | Ø39 | Ø57 | 4 | 0.6 |

| ZAR25W | CMI25W### | Ø95 | 79 | 38 | Ø31 | 31 | 41 | Ø13 | Ø58 | Ø84 | 3 | 1.3 |