Description

Operational Areas

These cylinders are used in industrial applications where a large number of cycles are required. They are used in blocking operations, in laboratories, and for tests that need pushing and pulling forces. The nitride anti-corrosive treatment makes them suitable for work in harsh environments and in the open air.

Accessories

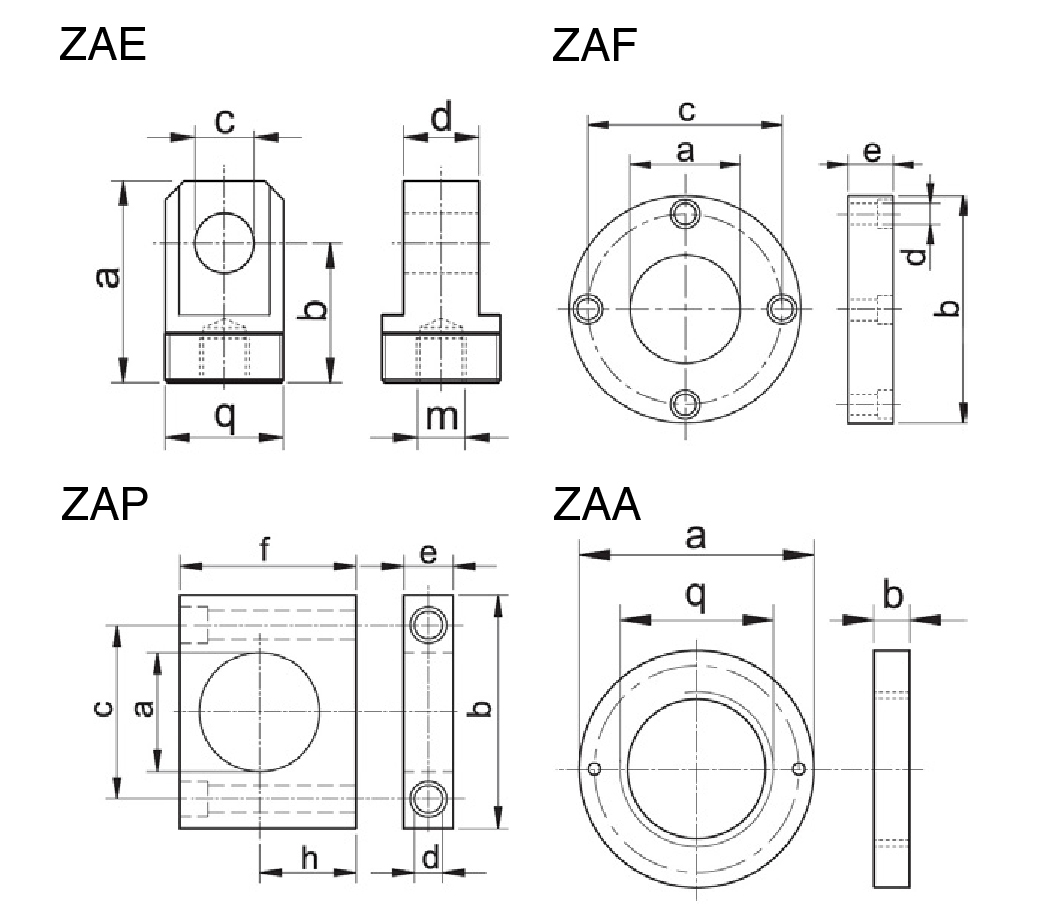

- ZAE Clevis eyes to be mounted on the rod or at the bottom.

- ZAF Flange to be mounted on the machined ends of the body.

- ZAP Plate to be mounted on the machined ends of the bod as an alternative to the flange.

- ZAA Nut to block either the flange or the plate.

Given their unusual mounting, these cylinders are supplied without the female K73F half-couplers, which can be ordered separately if required.

Selection Chart

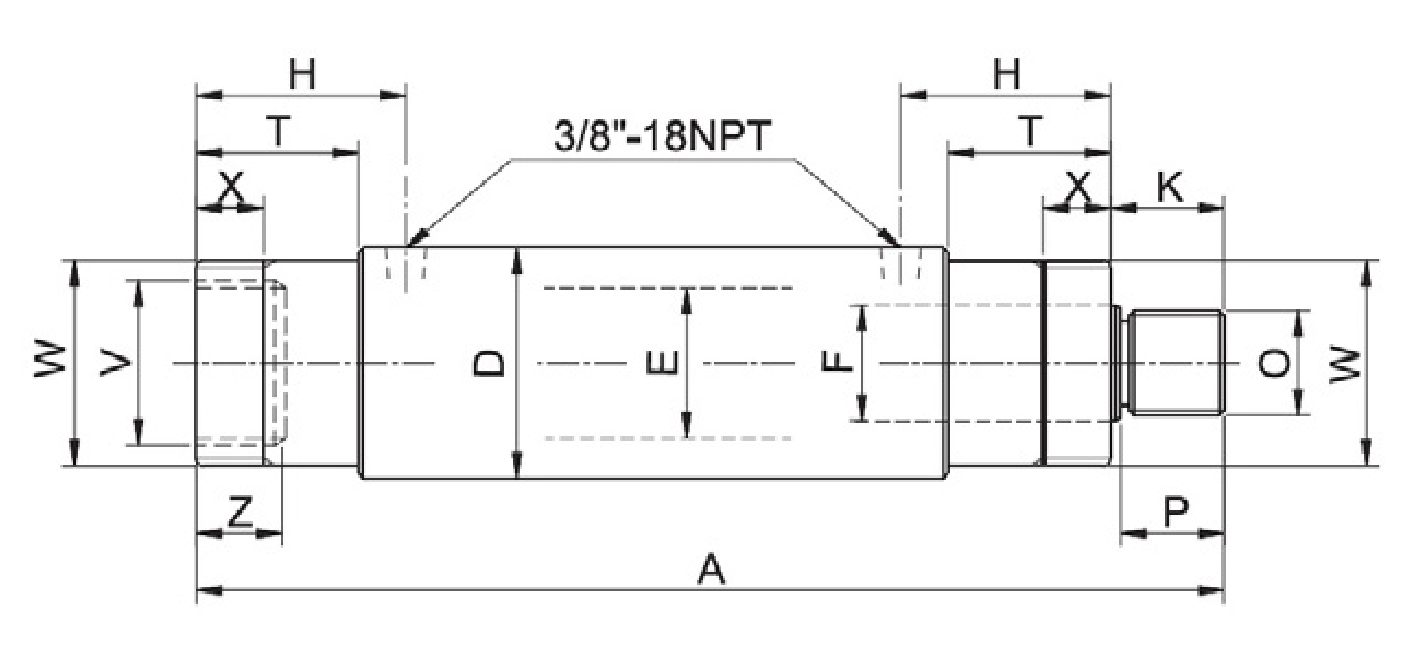

| PUSHING FORCE | PULLING FORCE | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME | MODEL | CLOSED HEIGHT | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLER HEIGHT | ROD PROJECTION | ROD THREAD | ROD THREAD LENGHT | COLLAR LENGHT | INTERNAL BASE THREAD | INTERNAL BASE THREAD DEPTH | COLLAR THREAD | COLLAR THREAD LENGHT | WEIGHT | * Nominal value, for precise capacity see kN |

| t*kN | t*kN | mm | cm² | cm² | cm3 | cm3 | Amm | Dmm | Emm | Fmm | Hmm | Kmm | Omm | Pmm | Tmm | Vmm | Zmm | Wmm | Xmm | kg | ||

|

|

|

30 | 7.1 | 3.9 | 21 | 12 | COD5N30 | 185 | 50 | 30 | 20 | 45 | 22 |

|

19 | 26 |

|

13 |

|

9 | 2.1 | |

| 80 | 57 | 31 | COD5N80 | 235 | 2.8 | |||||||||||||||||

| 160 | 113 | 63 | COD5N160 | 315 | 3.8 | |||||||||||||||||

|

|

|

30 | 13.9 | 8.9 | 42 | 27 | COD10N30 | 204 | 63 | 42 | 25 | 54 | 23 |

|

20 | 35 |

M42 |

15 |

|

15 | 3.6 | |

| 80 | 111 | 72 | COD10N80 | 254 | 4.5 | |||||||||||||||||

| 160 | 222 | 143 | COD10N160 | 334 | 5.8 | |||||||||||||||||

| 260 | 360 | 233 | COD10N260 | 434 | 7.3 | |||||||||||||||||

|

|

|

160 | 19.6 | 11.6 | 314 | 185 | COD15N160 | 376 | 80 | 50 | 32 | 71 | 31 |

|

28 | 52 |

|

27 |

|

16 | 10.8 | |

| 260 | 511 | 301 | COD15N260 | 476 | 13.9 | |||||||||||||||||

|

|

|

160 | 33.1 | 17.3 | 531 | 276 | COD25N160 | 412 | 92 | 65 | 45 | 84 | 41 |

|

38 | 65 |

|

30 |

|

20 | 15.5 | |

| 260 | 863 | 449 | COD25N260 | 512 | 19.4 |

Accessories ZAE – ZAF – ZAP – ZAA

| MODEL | a | b | c | d | e | f | h | m | q | kg |

| ZAE5 | 62 | 46 | 16 | 16 | – | – | – | M18x1.5 | M35z1.5 | 0.3 |

| ZAE10 | 77 | 58 | 20 | 25 | – | – | – | M22x1.5 | M42x1.5 | 0.6 |

| ZAE15 | 98 | 73 | 25 | 32 | – | – | – | M30x2 | M56x2 | 1.2 |

| ZAE25 | 112 | 80 | 32 | 38 | – | – | – | M42x1.5 | M70x2 | 2 |

| ZAF5 | 42 | 98 | 78.6 | 11 | 17 | – | – | – | – | 0.8 |

| ZAF10 | 56 | 118 | 99 | 11 | 23 | – | – | – | – | 1.5 |

| ZAF15 | 70 | 145 | 116 | 17 | 35 | – | – | – | – | 3.4 |

| ZAF25 | 85 | 168 | 136 | 17 | 45 | – | – | – | – | 6 |

| ZAP5 | 42 | 80 | 58 | 10.5 | 17 | 60 | 32 | – | – | 0.4 |

| ZAP10 | 56 | 110 | 82.6 | 13 | 23 | 82 | 45 | – | – | 1.1 |

| ZAP15 | 70 | 135 | 100 | 21 | 35 | 100 | 52 | – | – | 2.6 |

| ZAP25 | 85 | 160 | 118 | 26 | 45 | 125 | 63.5 | – | – | 5.1 |

| ZAA5 | 58 | 9 | – | – | – | – | – | – | M42x1.5 | 0.1 |

| ZAA10 | 78 | 12 | – | – | – | – | – | – | M56x2 | 0.3 |

| ZAA15 | 95 | 16 | – | – | – | – | – | – | M70x2 | 0.6 |

| ZAA25 | 108 | 20 | - | - | - | - | - | - | M85x2 | 0.8 |