Description

Operational Areas

They are very solid hydraulic cylinders recommended for lifting, pillaring, and lowering operations. Given their double-acting configuration, they are suggested for the synchronous lowering with split-flow power packs. They are mostly used in works of civil, naval, iron metallurgy, mechanical engineering, industrial assembly, and heavy carpentry where the quick and total return of the rod and the support of the load with the safety nut are fundamental requirements.

Options

- F Version, cylinders with base mounting holes for fixing purposes

Accessories

- Separate ZTT Tilt Saddle reduces the effects of possible off-centered loads.

Selection Chart

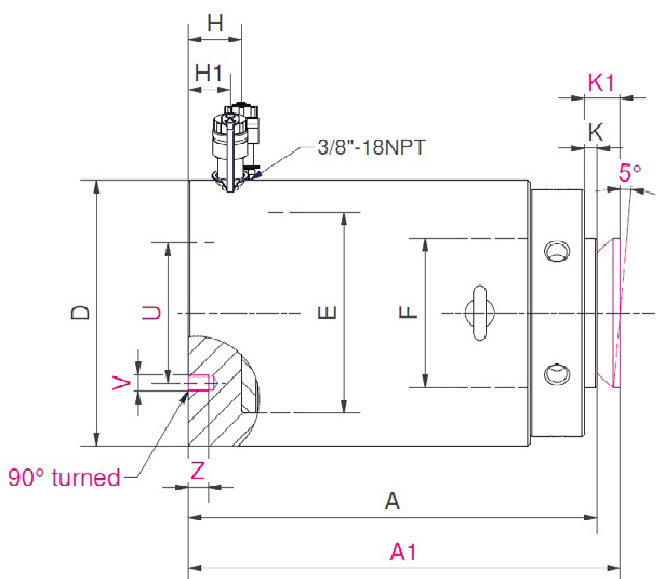

| USHING FORCE @700 BAR | PULLING FORCE @150 BAR | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH TILTING SADDLE MOUNTED | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLERS HEIGHT | ROD PROJECTION | ROD PROJECTION WITH TILTING SADDLE MOUNTED | Ø PCD MOUNTING HOLES | MOUNTING HOLES DEPTH | WEIGHT | *Nominal value, see kN for the exact force | |

| t*kN | t*kN | mm | cm² | cm² | cm³ | cm³ | Amm | A1mm | Dmm | Emm | Fmm | Hmm | H1mm | Kmm | K1mm | Umm | V / Zmm | kg | ||

|

|

|

100 | 147 | 31 | 1469 | 314 | COG100N100 | 272 | 292 | 188 | 140 | Tr 120 | 40 | 30 | 12 | 32 | 130 |

|

51 | |

| 150 | 2203 | 471 | COG100N150 | 322 | 342 | x6 | 59 | |||||||||||||

|

|

|

100 | 220 | 31 | 2199 | 314 | COG150N100 | 278 | 298 | 226 | 170 | Tr 130x10 | 40 | 30 | 12 | 32 | 130 |

|

73 | |

| 150 | 3299 | 471 | COG150N150 | 328 | 348 | 84 | ||||||||||||||

| 200 | 4398 | 628 | COG150N200 | 378 | 398 | 95 | ||||||||||||||

| 250 | 5498 | 785 | COG150N250 | 428 | 448 | 106 | ||||||||||||||

|

|

|

100 | 305 | 69 | 3045 | 689 | COG200N100 | 305 | 331 | 265 | 200 | Tr 165x10 | 50 | 38 | 13 | 39 | 140 |

|

109 | |

| 150 | 4568 | 1034 | COG200N150 | 355 | 381 | 125 | ||||||||||||||

| 200 | 6091 | 1378 | COG200N200 | 405 | 431 | 140 | ||||||||||||||

| 250 | 7613 | 1723 | COG200N250 | 455 | 481 | 156 | ||||||||||||||

|

|

|

100 | 443 | 69 | 4428 | 689 | COG300N100 | 336 | 363 | 356 | 270 | Tr 235x10 | 60 | 42 | 23 | 56 | 230 |

|

252 | |

| 150 | 6641 | 1034 | COG300N150 | 386 | 413 | 282 | ||||||||||||||

| 200 | 8855 | 1378 | COG300N200 | 436 | 463 | 313 | ||||||||||||||

| 250 | 11069 | 1723 | COG300N250 | 486 | 513 | 343 | ||||||||||||||

|

|

|

100 | 560 | 117 | 5600 | 1168 | COG400N100 | 380 | 413 | 356 | 270 | Tr 235x10 | 60 | 42 | 23 | 56 | 230 |

|

252 | |

| 150 | 8400 | 1752 | COG400N150 | 430 | 463 | 282 | ||||||||||||||

| 200 | 11200 | 2337 | COG400N200 | 480 | 523 | 313 | ||||||||||||||

| 250 | 14000 | 2921 | COG400N250 | 530 | 563 | 343 | ||||||||||||||

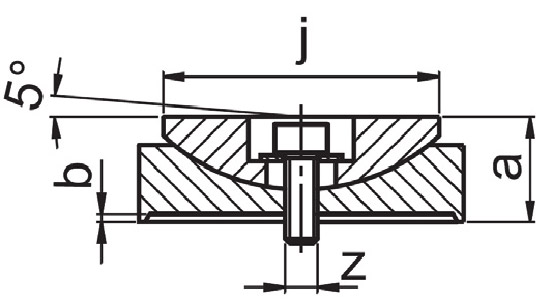

Accessories ZTT Tilt Saddle

| MODEL | FOR USE WITH | a | b | c | j | u | z | w | kg |

| ZTT101 | COG100N # # # | 22 | 32 | 10 | 88 | 85 | 6.5 | 65 | 1.6 |

| ZTT151 | COG150N # # # | 32 | 42 | 118 | 105 | 80 | 3.2 | ||

| ZTT201 | COG200N # # # | 39 | 51 | 12 | 148 | 135 | 8.5 | 110 | 6.5 |

| ZTT301 | COG300N # # # | 43 | 55 | 158 | 175 | 150 | 11 | ||

| ZTT401 | COG400N # # # | 56 | 68 | 196 | 215 | 190 | 20.2 |