Description

Operational Areas

They are very solid cylinders recommended for pile testing operations and in situations in which the weight can be dangerous due to harsh conditions of adjustments or difficulties in transport. The oil return feature makes them suitable for synchronous lifting and lowering with SPLIT FLOW power packs.

Option

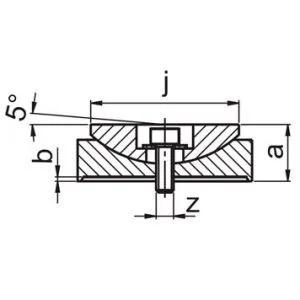

- T version: Cylinder with integrated tilt saddle.

- F version: Cylinder with base mounting holes for fixing purposes.

Accessories

- ZTT tilt saddle reduces the effects of any possible off-centred load.

Selection Chart

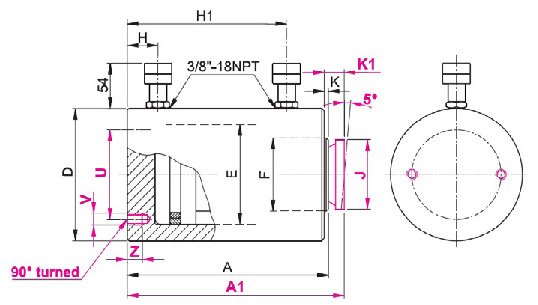

| PUSHING FORCE | PULLING FORCE | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH INTEGRATED TILT SADDLE | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLERS HEIGHT | Ø INTEGRADTED TILT SADDLE | ROD PROJECTION | ROD PROJECTION WITH INTEGRATED TILT SADDLE | PCD MOUNTING HOLES | MOUNTING HOLES DEPTH | WEIGHT | |

| t* kN | t* kN | mm | cm² | cm² | cm3 | cm3 | Amm | A1mm | Dmm | Emm | Fmm | Hmm | H1 | Jmm | K | K1mm | Umm | V / Z mm | kg | |

|

|

|

50 | 70.1 | 20.6 | 354 | 103 | COL50N50 | 149 | 154 | 135 | 95 | 80 | 20 | 104 | 68 | 1 | 6 | 95 |

|

10 |

| 100 | 709 | 206 | COL50N100 | 199 | 204 | 154 | 13 | |||||||||||||

| 150 | 1063 | 309 | COL50N150 | 249 | 254 | 204 | 16 | |||||||||||||

|

|

|

50 | 132.7 | 54.1 | 664 | 271 | COL100N50 | 198 | 205 | 180 | 130 | 100 | 32 | 127 | 88 | 2 | 9 | 130 |

|

17 |

| 100 | 1327 | 542 | COL100N100 | 248 | 255 | 177 | 20 | |||||||||||||

| 150 | 1991 | 813 | COL100N150 | 298 | 305 | 227 | 23 | |||||||||||||

| 200 | 2655 | 1084 | COL100N200 | 348 | 355 | 277 | 26 | |||||||||||||

|

|

|

50 | 201 | 88 | 1005 | 440 | COL150N50 | 214 | 223 | 228 | 160 | 120 | 35 | 136 | 118 | 3 | 12 | 130 |

|

26 |

| 100 | 2011 | 880 | COL150N100 | 264 | 273 | 186 | 31 | |||||||||||||

| 150 | 3016 | 1319 | COL150N150 | 314 | 323 | 236 | 36 | |||||||||||||

| 200 | 4021 | 1759 | COL150N200 | 364 | 373 | 286 | 41 | |||||||||||||

| 250 | 5027 | 2199 | COL150N250 | 414 | 423 | 336 | 45 | |||||||||||||

|

|

|

50 | 283.4 | 106.9 | 1418 | 534 | COL200N50 | 234 | 243 | 265 | 190 | 150 | 42 | 152 | 148 | 3 | 12 | 140 |

|

44 |

| 100 | 2835 | 1068 | COL200N100 | 284 | 293 | 202 | 51 | |||||||||||||

| 150 | 4253 | 1602 | COL200N150 | 334 | 343 | 252 | 58 | |||||||||||||

| 200 | 5671 | 2136 | COL200N200 | 384 | 393 | 302 | 65 | |||||||||||||

| 250 | 7088 | 2670 | COL200N250 | 434 | 443 | 352 | 72 | |||||||||||||

| 300 | 8506 | 3204 | COL200N300 | 484 | 493 | 402 | 79 | |||||||||||||

|

|

|

100 | 346.3 | 119.3 | 3464 | 1194 | COL250N100 | 305 | 314 | 295 | 210 | 170 | 48 | 214 | 158 | 3 | 12 | 150 |

|

66 |

| 150 | 5195 | 1791 | COL250N150 | 355 | 364 | 264 | 75 | |||||||||||||

| 200 | 6927 | 2388 | COL250N200 | 405 | 414 | 314 | 84 | |||||||||||||

|

|

|

100 | 415.4 | 131.9 | 4155 | 1319 | COL300N100 | 314 | 323 | 320 | 230 | 190 | 53 | 217 | 158 | 3 | 12 | 170 |

|

80 |

| 150 | 6232 | 1979 | COL300N150 | 364 | 373 | 267 | 90 | |||||||||||||

| 200 | 8310 | 2639 | COL300N200 | 414 | 423 | 317 | 101 | |||||||||||||

Accessories ZTT Tilt Saddle

| PUSHING FORCE | PULLING FORCE | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME |

| ZTT50 | COL50N # # # | 25 | 1 | 68 | M8 | 0.9 |

| ZTT100 | COL100N # # # | 34 | 2 | 88 | M10 | 1.7 |

| ZTT150 | COL150N # # # | 45 | 3 | 118 | 3.4 | |

| ZTT200 | COL200N # # # | 54 | 148 | 7 | ||

| ZTT250 | COL250N # # # | 58 | 158 | 9.5 | ||

| ZTT300 | COL300N # # # | 11.3 |