Description

Operational Areas

They are extremely solid hydraulic cylinders highly recommended for lifting, holding, and lowering operations. They are ideally built for applications in civil engineering and marine engineering and in the construction industry.

Options

- T version: Cylinder with integrated tilt saddle.

- F version: Cylinder with base mounting holes for fixing purposes.

Accessories

- Separate ZTT tilt saddle reduces the effects of any possible off-centred load.

Selection Chart

| Pushing force | Pulling force | Stroke | Pushing effective area | Pulling effective area | Pushing oil volume | Pulling oil volume | MODEL | Closed Height | Closed height with integrated tilt saddle | Ø External | Ø Piston | Ø Rod | Couplers height | Ø Integrated tilt saddle | Rod projection | Rod projection with integrated tilt saddle | PCD mounting holes | Mounting holes Depth | Weight | * Nominal value, see kN for the exact force | |

| t*kN | t*kN | mm | cm² | cm² | cm3 | cm3 | Amm | A1mm | Dmm | Emm | Fmm | Hmm | H1mm | Jmm | Kmm | K1mm | Umm | V / Zmm | kg | ||

|

|

|

50 | 70.1 | 20.6 | 354 | 103 | COS50N50 | 149 | 154 | 127 | 95 | 80 | 20 | 104 | 68 | 1 | 6 | 95 |

|

14 | |

| 100 | 709 | 206 | COS50N100 | 199 | 204 | 154 | 18 | ||||||||||||||

| 150 | 1063 | 309 | COS50N150 | 249 | 254 | 204 | 22 | ||||||||||||||

|

|

|

50 | 132.7 | 54.1 | 664 | 271 | COS100N50 | 171 | 178 | 175 | 130 | 100 | 28 | 124 | 88 | 2 | 9 | 130 |

|

30 | |

| 100 | 1327 | 542 | COS100N100 | 221 | 228 | 174 | 38 | ||||||||||||||

| 150 | 1991 | 813 | COS100N150 | 271 | 278 | 224 | 45 | ||||||||||||||

| 200 | 2655 | 1084 | COS100N200 | 321 | 328 | 274 | 52 | ||||||||||||||

|

|

|

25 | 201 | 88 | 503 | 220 | COS150N25 | 167 | 176 | 213 | 160 | 120 | 30 | 106 | 118 | 3 | 12 | 130 |

|

45 | |

| 50 | 1005 | 440 | COS150N50 | 192 | 201 | 131 | 50 | ||||||||||||||

| 100 | 2011 | 880 | COS150N100 | 242 | 251 | 181 | 61 | ||||||||||||||

| 150 | 3016 | 1319 | COS150N150 | 292 | 301 | 231 | 71 | ||||||||||||||

| 200 | 4021 | 1759 | COS150N200 | 342 | 351 | 281 | 82 | ||||||||||||||

| 250 | 5027 | 2199 | COS150N250 | 392 | 401 | 331 | 93 | ||||||||||||||

Selection Chart

| PUSHING FORCE | PULLING FORCE | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH INTEGRATED TILT SADDLE | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLERS HEIGHT | Ø INTEGRATED TILT SADDLE | ROD PROJECTION | ROD PROJECTION WITH INTEGRATED TILT SADDLE | Ø PCD MOUNITNG HOLES | MOUNTING HOLES DEPTH | WEIGHT | * Nominal value, see kN for the exact force | |

| t*kN | t*kN | mm | cm² | cm² | cm3 | cm3 | Amm | A1mm | Dmm | Emm | Fmm | Hmm | H1mm | Jmm | Kmm | K1mm | Umm | V / Zmm | kg | ||

|

|

|

25 | 283.4 | 106.9 | 709 | 267 | COS200N25 | 181 | 190 | 252 | 190 | 150 | 32 | 117 | 148 | 3 | 12 | 140 |

|

69 | |

| 50 | 1418 | 534 | COS200N50 | 206 | 215 | 142 | 76 | ||||||||||||||

| 100 | 2835 | 1068 | COS200N100 | 256 | 265 | 192 | 92 | ||||||||||||||

| 150 | 4253 | 1602 | COS200N150 | 306 | 315 | 242 | 107 | ||||||||||||||

| 200 | 5671 | 2136 | COS200N200 | 356 | 365 | 292 | 123 | ||||||||||||||

| 250 | 7088 | 2670 | COS200N250 | 406 | 415 | 342 | 138 | ||||||||||||||

| 300 | 8506 | 3204 | COS200N300 | 456 | 465 | 392 | 153 | ||||||||||||||

|

|

|

25 | 346.3 | 119.3 | 866 | 298 | COS250N25 | 197 | 206 | 280 | 210 | 170 | 34 | 128 | 158 | 3 | 12 | 150 |

|

92 | |

| 50 | 1732 | 597 | COS250N50 | 222 | 231 | 153 | 102 | ||||||||||||||

| 100 | 3464 | 1194 | COS250N100 | 272 | 281 | 203 | 122 | ||||||||||||||

| 150 | 5195 | 1791 | COS250N150 | 322 | 331 | 253 | 141 | ||||||||||||||

| 200 | 6927 | 2388 | COS250N200 | 372 | 381 | 303 | 161 | ||||||||||||||

| 250 | 8659 | 2985 | COS250N250 | 422 | 431 | 353 | 180 | ||||||||||||||

| 300 | 10391 | 3581 | COS250N300 | 472 | 481 | 403 | 200 | ||||||||||||||

|

|

|

25 | 415.4 | 131.9 | 1039 | 330 | COS300N25 | 203 | 212 | 305 | 230 | 190 | 38 | 130 | 158 | 3 | 12 | 170 |

|

113 | |

| 50 | 2077 | 660 | COS300N50 | 228 | 237 | 155 | 125 | ||||||||||||||

| 100 | 4155 | 1319 | COS300N100 | 278 | 287 | 205 | 148 | ||||||||||||||

| 150 | 6232 | 1979 | COS300N150 | 328 | 337 | 255 | 172 | ||||||||||||||

| 200 | 8310 | 2639 | COS300N200 | 378 | 387 | 305 | 195 | ||||||||||||||

| 250 | 10387 | 3299 | COS300N250 | 428 | 437 | 355 | 219 | ||||||||||||||

| 300 | 12464 | 3958 | COS300N300 | 478 | 487 | 405 | 242 | ||||||||||||||

Selection Chart

| PUSHING FORCE | PULLING FORCE | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME | MODEL | CLOSED HEIGHT | CLOSED HEIGHT WITH INTEGRATED TILT SADDLE | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLERS HEIGHT | Ø INTEGRATED TILT SADDLE | ROD PROJECTION | ROD PROJECTION WITH INTEGRATED TILT SADDLE | Ø PCD MOUNITNG HOLES | MOUNTING HOLES DEPTH | WEIGHT | * Nominal value, see kN for the exact force | |

| t*kN | t*kN | mm | cm² | cm² | cm3 | cm3 | Amm | A1mm | Dmm | Emm | Fmm | Hmm | H1mm | Jmm | Kmm | K1mm | Umm | V / Zmm | kg | ||

|

|

|

25 | 490.1 | 144.4 | 1227 | 361 | COS350N25 | 210 | 222 | 332 | 250 | 210 | 39 | 132 | 196 | 3 | 15 | 200 |

|

138 | |

| 50 | 2454 | 723 | COS350N50 | 235 | 247 | 157 | 153 | ||||||||||||||

| 100 | 4909 | 1445 | COS350N100 | 285 | 297 | 207 | 183 | ||||||||||||||

| 150 | 7363 | 2168 | COS350N150 | 335 | 347 | 257 | 213 | ||||||||||||||

| 200 | 9817 | 2890 | COS350N200 | 385 | 397 | 307 | 242 | ||||||||||||||

| 250 | 12272 | 3613 | COS350N250 | 435 | 447 | 357 | 272 | ||||||||||||||

| 300 | 14726 | 4335 | COS350N300 | 485 | 497 | 407 | 302 | ||||||||||||||

|

|

|

25 | 572.6 | 157 | 1431 | 393 | COS400N25 | 217 | 229 | 356 | 270 | 230 | 42 | 135 | 196 | 3 | 15 | 230 |

|

165 | |

| 50 | 2863 | 785 | COS400N50 | 242 | 254 | 160 | 182 | ||||||||||||||

| 100 | 5726 | 1571 | COS400N100 | 292 | 304 | 210 | 215 | ||||||||||||||

| 150 | 8588 | 2356 | COS400N150 | 342 | 354 | 260 | 248 | ||||||||||||||

| 200 | 11451 | 3142 | COS400N200 | 392 | 404 | 310 | 281 | ||||||||||||||

| 250 | 14314 | 3927 | COS400N250 | 442 | 454 | 360 | 313 | ||||||||||||||

| 300 | 17177 | 4712 | COS400N300 | 492 | 504 | 410 | 346 | ||||||||||||||

|

|

|

25 | 706.9 | 216 | 1767 | 540 | COS500N25 | 225 | 237 | 396 | 300 | 250 | 50 | 140 | 196 | 3 | 15 | 250 |

|

212 | |

| 50 | 3534 | 1080 | COS500N50 | 250 | 262 | 165 | 232 | ||||||||||||||

| 100 | 7069 | 2160 | COS500N100 | 300 | 312 | 215 | 271 | ||||||||||||||

| 150 | 10603 | 3240 | COS500N150 | 350 | 362 | 265 | 312 | ||||||||||||||

| 200 | 14137 | 4320 | COS500N200 | 400 | 412 | 315 | 352 | ||||||||||||||

| 250 | 17671 | 5400 | COS500N250 | 450 | 462 | 365 | 391 | ||||||||||||||

| 300 | 21206 | 6480 | COS500N300 | 500 | 512 | 415 | 431 | ||||||||||||||

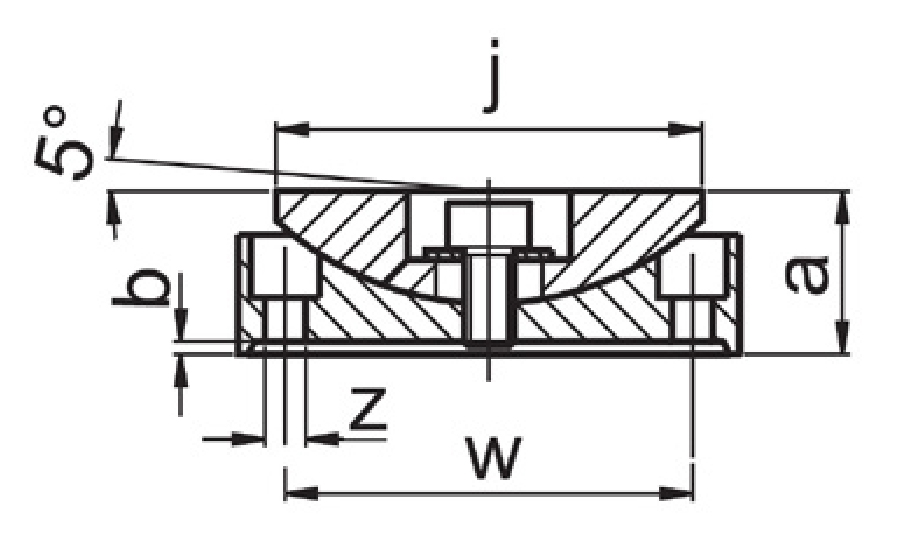

Accessories ZTT Tilt Saddles

| MODEL | FOR USE WITH | a | b | j | z | kg |

| ZTT50 | COS50N # # # | 25 | 1 | 68 | M8 | 0.9 |

| ZTT100 | COS100N # # # | 34 | 2 | 88 | M10 | 1.7 |

| ZTT150 | COL150N # # # | 45 | 3 | 118 | 3.4 | |

| ZTT200 | COL200N # # # | 54 | 148 | 7 | ||

| ZTT250 | COL250N # # # | 58 | 158 | 9.5 | ||

| ZTT300 | COL300N # # # | 11 | ||||

| ZTT350 | COS350N # # # | 71 | 19 | M12 | 18 | |

| ZTT400 | COS400N # # # | 20.7 | ||||

| ZTT500 | COS500N # # # | 23.8 |