Description

Operational Areas

- PN13# Series Single-stage pumps with 1.2–2.2-litre reservoirs for single-acting cylinders with short strokes and small/medium oil capacities.

- PN14# Series Double-stage pumps with 1.2-2.2-litre reservoirs with a pressure relief valve on the first stage are recommended for single-acting cylinders with medium strokes and medium oil capacities.

- PN16# Series Double-stage pumps with 2.2–4.3–7.8-litre reservoirs with an unloading valve to facilitate the pumping on the second stage are recommended for single-acting cylinders with long strokes and large oil capacities.

- PN26# Series Double-stage pumps with 2.2–4.3–7.8-litre reservoirs with an unloading valve to facilitate the pumping on the second stage; with a 4-way valve for double-acting cylinders with long strokes and large oil capacities.

- PN46# Series Pumps like the PN26# Series but equipped with an additional pilot check valve in order to maintain the load while moving the lever and to control the lowering of the cylinder under load.

- PN13110-PN16#10 Series Used in extracting operations, in lab tests, and to operate hydraulic bolt tensioners models UTN and UTH.

- PN13116–PPN16#16 Series Used in all bearing extractions and to operate hydraulic bolt UTV tensioners.

- PN13128–PPN16#28–PPN13240 Series They are most useful and effective in cases of laddering of bearings, tightenings, pretensioning of studs, burst tests, and calibrations.

All 700 bar models have:

- Externally adjustable relief valve;

- Side port 1/4” NPT for the direct fitting of the G106L gauge (PN26# range excluded);

- 1/4” NPT port to insert directly the G106 gauge only on the PN46# pump

- Fixing port;

- Tank from 1.2–2.2–4.3 e 7.8 lt.

All 1000 / 1600 / 2800 / 4000 bar models have:

- Double stage (except PN13110/16/28 and PN13110 models);

- Externally adjustable low and high pressure relief valves;

- Second port (also usable as gauge port) only on PN13110/16/28, PN16#28, and PN13240 models;

- Fixing port;

- Tank from 1.2–2.2–4.3 e 7.8 lt.

All PN pumps can work vertically with the pumping head pointing downwards.

For a proper fit, they can be fastened by using the ZPN#MOD kit.

The usable oil volume is 100% of the reservoir capacity with 1 and 2 litre tanks, thanks to the filler cap positioned at the end of the tank.

Double-acting pumps

The PN26# pump series is equipped with a 4-way manual valve in order to use oil return or double-acting cylinders for traction, pushing, and lifting operations.

While moving the lever to a different position, for instance, the load is not held, the return is controlled by the by-pass valve, and in order to have a total return of the cylinder, place the valve in the return position.

Double acting with a piloted check valve:

Differently from the PN26# pump series, the PN46# series allows a perfectly controlled lowering under load by acting on the pump with the valve in discharge position thanks to the presence of a piloted check valve that intercepts port A. The PN46# pumps are equipped with a port for the mounting of 1/4” NPT manometer model G106.

In order to fix the 1 and 2 litre pumps correctly, use the port at the bottom, paying attention not to tighten the screws too much to avoid possible deformations or oil losses. We recommend to use the ZPNB kit.

If requested, we are able to supply versions to be used with fluids that are different from mineral oil.

Selection Chart

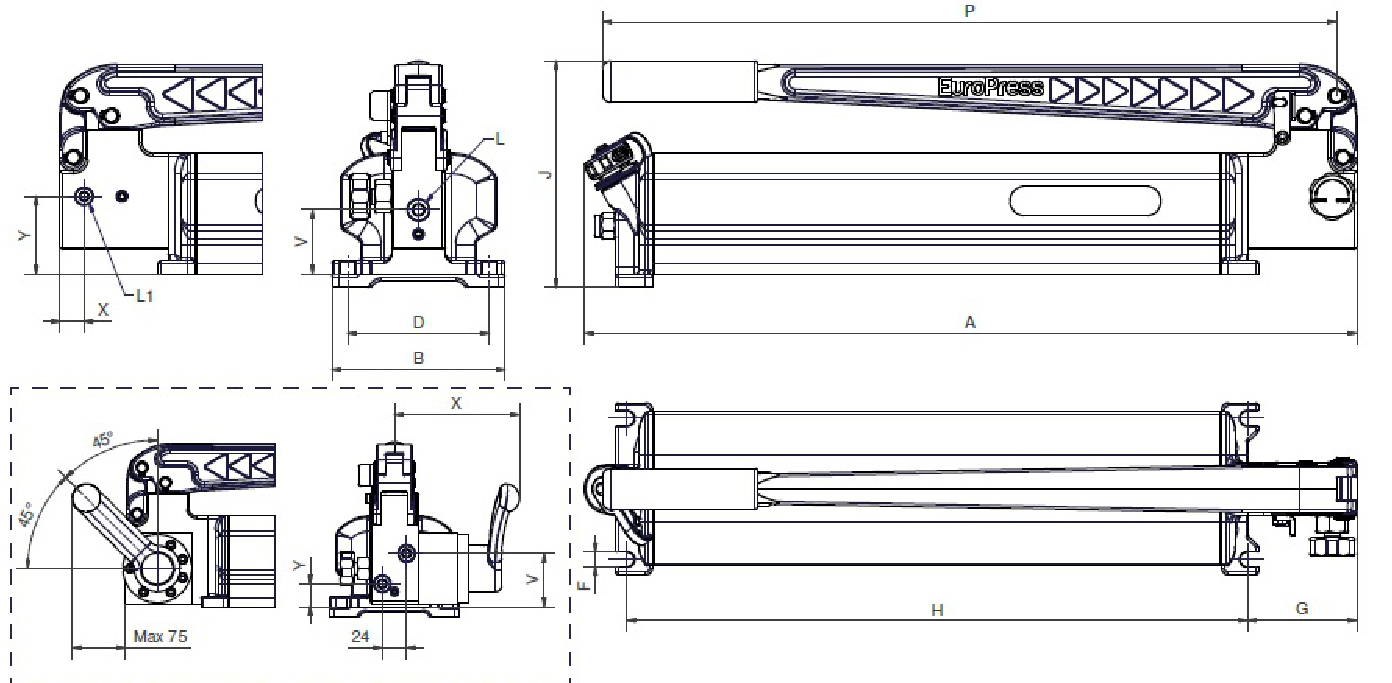

| Pressure 1st stage | Pressure 2nd stage | Oil delivery for stroke 1st stage | Oil delivery for stroke 2nd stage | Handle effort | For use with | Reservoir capacity | Usable oil volume | MODEL | DIMENSION MM | WEIGHT | ||||||||||||

| bar | bar | cm³ | cm³ | N | Litres | Litres | A | B | D | G | H | F | J | L | L1 | P | V | X | Y | kg | ||

| - | 700 | - | 2.7 | 363 | Single acting | 1.2 | 1 | PN131 | 572 | 115 | 90 | 83 | 460 | 11 | 154 | 3/8” NPT | 1/2”BSP | 544 | 32 | 18 | 42 | 4.8 |

| 2.2 | 2 | PN132 | 572 | 128 | 105 | 83 | 460 | 11 | 169 | 544 | 47 | 18 | 57 | 6.2 | ||||||||

| 30 | 13.7 | 2.2 | 380 | 1.2 | 1 | PN141 | 572 | 115 | 90 | 83 | 460 | 11 | 154 | 544 | 32 | 18 | 42 | 4.8 | ||||

| 2.2 | 2 | PN142 | 572 | 128 | 105 | 83 | 460 | 11 | 169 | 544 | 47 | 18 | 57 | 6.2 | ||||||||

| 70 | 28.5 | 2.7 | 363 | 2.2 | 2 | PN162 | 572 | 128 | 105 | 83 | 460 | 11 | 173 | 3/8” NPT | 1/4” NPT | 544 | 32 | 18 | 55 | 6.6 | ||

| 4.3 | 3.8 | PN164 | 572 | 190 | 176 | 90 | 471 | 9 | 173 | 544 | 32 | 18 | 55 | 9.8 | ||||||||

| 7.8 | 7.2 | PN168 | 652 | 270 | 256 | 90 | 551 | 9 | 173 | 3/8” NPT | - | 544 | 32 | 18 | 55 | 14.5 | ||||||

| Double acting | 2.2 | 2 | PN262 | 572 | 128 | 105 | 83 | 460 | 11 | 173 | 544 | 52 | 124 | 22 | 7.4 | |||||||

| 4.3 | 3.8 | PN264 | 572 | 190 | 176 | 90 | 471 | 9 | 173 | 544 | 52 | 124 | 22 | 10.6 | ||||||||

| 7.8 | 7.2 | PN268 | 652 | 270 | 256 | 90 | 551 | 9 | 173 | 3/8” NPT | 1/4” NPT | 544 | 52 | 124 | 22 | 15.3 | ||||||

| Piloted check | 2.2 | 2 | PN462 | 572 | 128 | 105 | 83 | 460 | 11 | 173 | 544 | 52 | 148 | 22 | 7.7 | |||||||

| 4.3 | 3.8 | PN464 | 572 | 190 | 176 | 90 | 471 | 9 | 173 | 544 | 52 | 148 | 22 | 10.9 | ||||||||

| 7.8 | 7.2 | PN468 | 652 | 270 | 256 | 90 | 551 | 9 | 173 | 544 | 52 | 148 | 22 | 15.6 | ||||||||

| - | 1000 | - | 1.4 | 274 | Single acting | 1.2 | 1 | PN13110 | 572 | 115 | 90 | 83 | 460 | 11 | 154 | 1/2”BSP | 544 | 31 | * | – | 3 | |

| 20 | 28.5 | 385 | 2.2 | 2 | PN16210 | 572 | 128 | 105 | 83 | 460 | 11 | 173 | 1/4” BSP 120° | - | 544 | 30 | – | – | 6.6 | |||

| 4.3 | 3.8 | PN16410 | 572 | 190 | 176 | 90 | 471 | 9 | 173 | 544 | 30 | – | – | 9.8 | ||||||||

| 7.8 | 7.2 | PN16810 | 652 | 270 | 256 | 90 | 551 | 9 | 173 | 544 | 30 | – | – | 14.5 | ||||||||

| - | 1600 | - | 1.4 | 437 | 1.2 | 1 | PN13116 | 572 | 115 | 90 | 83 | 460 | 11 | 154 | 1/2”BSP | 544 | 31 | * | – | 3 | ||

| 15 | 28.5 | 522 | 2.2 | 2 | PN16216 | 572 | 128 | 105 | 83 | 460 | 11 | 173 | 1/4” BSP 120° | - | 544 | 30 | – | – | 6.6 | |||

| 4.3 | 3.8 | PN16416 | 572 | 190 | 176 | 90 | 471 | 9 | 173 | 544 | 30 | – | – | 9.8 | ||||||||

| 7.8 | 7.2 | PN16816 | 652 | 270 | 256 | 90 | 551 | 9 | 173 | 544 | 30 | – | – | 14.5 | ||||||||

| - | 2800 | - | 0.8 | 432 | 1.2 | 1 | PN13128 | 572 | 115 | 90 | 83 | 460 | 11 | 154 | 3/4” – 16 UNF | 3/8”BSP | 544 | 35 | * | – | 3 | |

| 10 | 28.5 | 515 | 2.2 | 2 | PN16228 | 572 | 128 | 105 | 83 | 460 | 11 | 173 | 3/4” – 16 UNF | 544 | 42 | 28 | 42 | 6.8 | ||||

| 4.3 | 3.8 | PN16428 | 572 | 190 | 176 | 90 | 471 | 9 | 173 | 544 | 42 | 28 | 42 | 10 | ||||||||

| 7.8 | 7.2 | PN16828 | 652 | 270 | 256 | 90 | 551 | 9 | 173 | 544 | 32 | 18 | 42 | 4.8 | ||||||||

| - | 4000 | - | 0.55 | 530 | 2.2 | 2 | PN13240 | 567 | 128 | 105 | 83 | 460 | 11 | 173 | M16 x 1.5 | 544 | 47 | 18 | 57 | 6.2 | ||

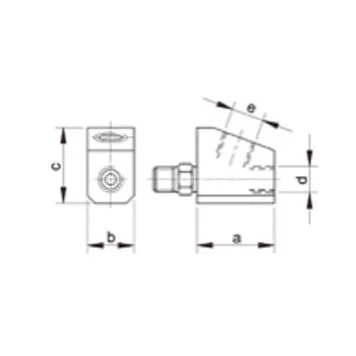

Accessories ZPS – ZPF Gauge Adaptors – 700 Bar

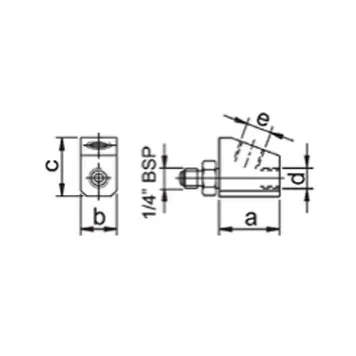

| MODEL | for pumps | a | b | c | d | e | kg | |

|

ZPS12 (Screw Connection) | SERIES PN13# PN14# PN16# | 50 | 30 | 48 | 3/8’’ NPT | 1/2’’ BSP | 0.25 |

|

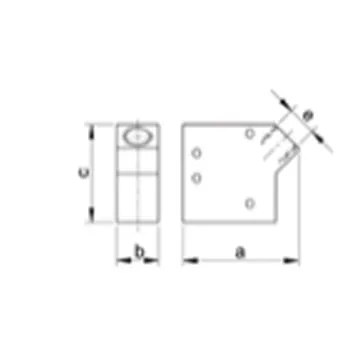

ZPF12 (Flange Connection) | SERIES PN16# | 45 | 45 | 60 | 3/8’’ NPT | 1/2’’ BSP | 0.9 |

|

ZPF121 (Plate Attachment) | SERIES PN26# | 83 | 30 | 70 | – | 1/2’’ BSP | 0.37 |

Accessories ZPS – ZPF Gauges Adaptors – ZPD Valves 1000/1600/2800 Bar

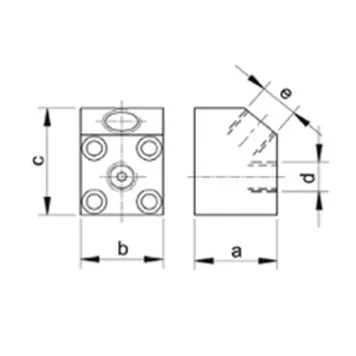

| MODEL | For pumps | For gauge | Press. max bar | a | b | c | d | e | kg | ||

|

|

ZPS53(adattatore manometro a vite) | SERIE PN16#10 PN16#16 | G10 | 1000 | 50 | 30 | 48 | 3/8’’ NPT | 1/2’’ BSP | 0.9 |

| ZPF14(adattatore manometro flangiato) | SERIE PN16#10 PN16#16 | G10 G16 | 1600 | 45 | 45 | 60 | 1/4’’ BSP 120° | 1/2’’ BSP | 0.9 | ||

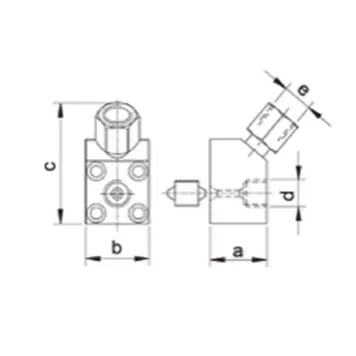

|

|

ZPF73(adattatore manometro flangiato) | SERIE PN16#28 | G30 / G40 + RN28 | 2800 | 40 | 45 | 85 | 3/4’’ –16UNF | 1/2’’ BSPgirevole | 1 |

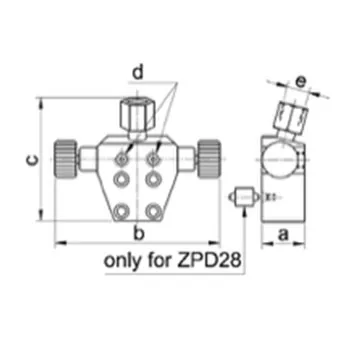

| ZPD16(valvola a doppio spillo flangiata) | SERIE PN16#10 PN16#16 | G10 G16 | 1600 | 40 | 155 | 112 | 1/4’’ BSP 120° | 1/2’’ BSPgirevole | 1 | ||

| ZPD28(valvola a doppio spillo flangiata) | SERIE PN16#28 | G30 / G40 + RN28 | 2800 |