Description

Operational Areas

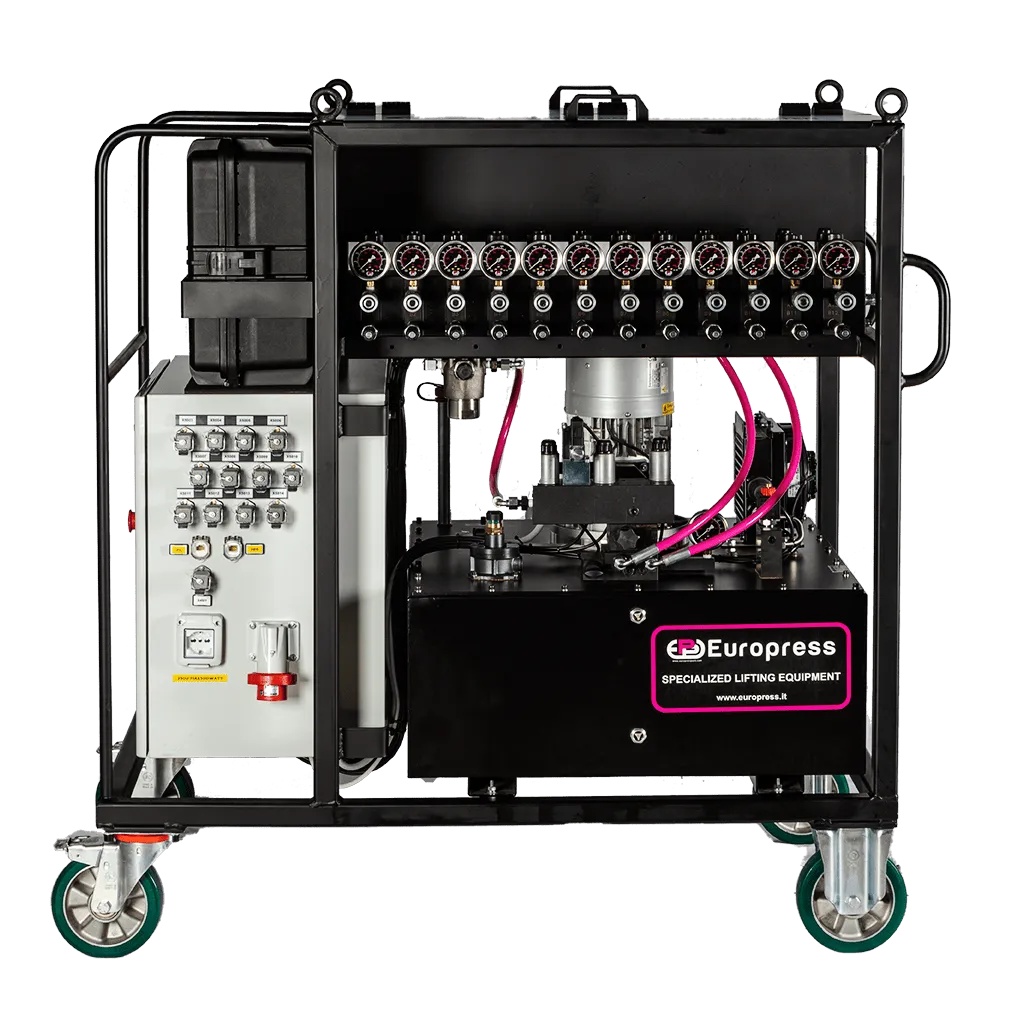

Our Synchrolift system is necessary every time hydraulic cylinders with different loads are required to lift and lower the same rate (e.g., lifting a 3000 t bridge with 1 mm precision or squaring a building damaged by seismic activity are only two of the many applications of a synchronised lifting system).

- Hydraulic power pack

- Electronic control base

- Laptop PC or touchscreen display

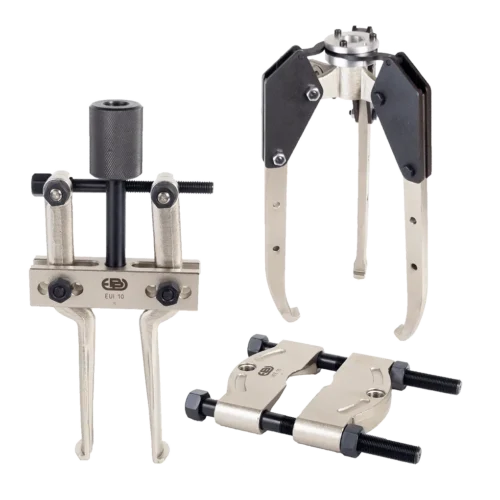

- Hydraulic cylinders

- Stroke transducers

- High-pressure hoses

- Electric connection cables

- Structure to be lifted

Selection Chart

| CONTROL SYSTEM | |||

| SYNCHRO 4 punti | ESY4V | Electronic control base (4 points) with dedicated PLC + note book with included software (Windows area) to display and control operations and to book data + 4 linear stroke transducers (1 for each lifting point) + group of control valves | |

| ESY4VC | Electronic control base (4 points) with dedicated PLC + note book with included software (Windows area) to display and control operations and to book data + 4 linear stroke transducers (1 for each lifting point) + group of control valves + trolley + cover | ||

| SYNCHRO 8 punti | ESY8V | Electronic control base (8 points) with dedicated PLC + note book with included software (Windows area) to display and control operations and to book data + 8 linear stroke transducers (1 for each lifting point) + group of control valves | |

| ESY8VC | Electronic control base (8 points) with dedicated PLC + note book with included software (Windows area) to display and control operations and to book data + 8 linear stroke transducers (1 for each lifting point) + group of control valves + trolley + cover | ||

| HYDRAULIC COMPONENTS | |||

| Power Source | Customised hydraulic power pack | ||

| Cylinders | Standard hydraulic cylinders and/or as chosen by client | ||

| Connections | Hoses, fittings and couplers according to your needs | ||