Description

Operational Areas

These extra-compact, lightweight cylinders are the ideal solution to operate in the narrowest working areas. They are used for the lifting of machinery, transformers, and bridge sections, while in the shipbuilding industry they can be used to raise engines into position and remove propellers.

Accessories

- ZTT tilt saddle reduces the effects of any possible off-centred load.

Standard

- Tilt saddle mounting holes

Selection Chart

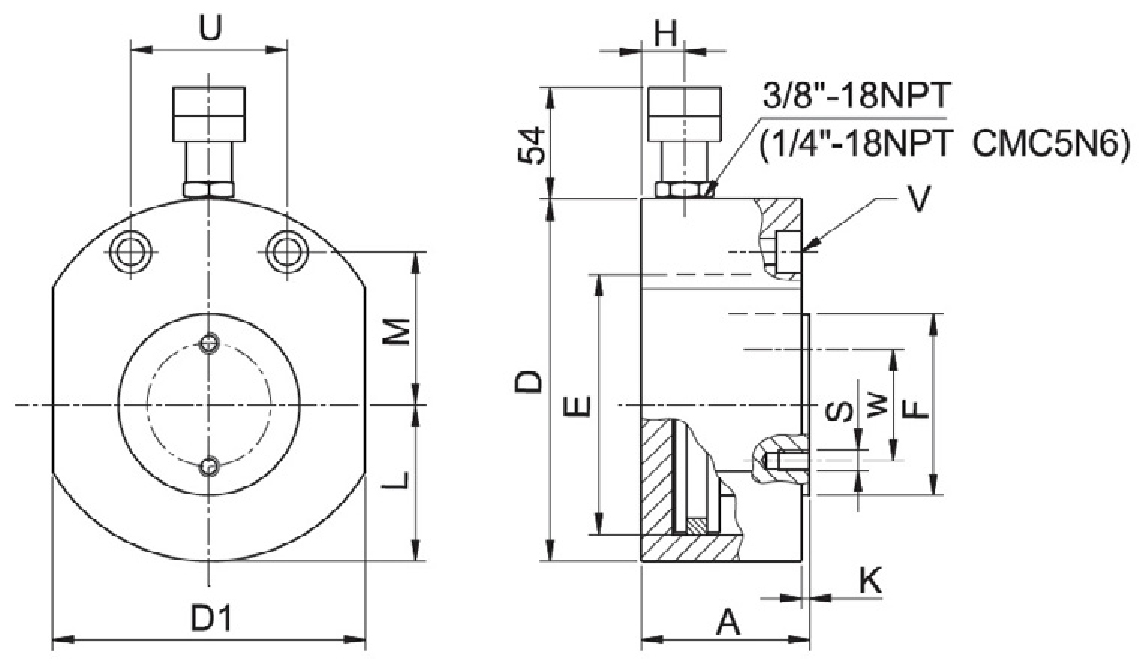

| PUSHING FORCE | STROKE | EFFECTIVE AREA | OIL VOLUME | MODEL | CLOSED HEIGHT | Ø EXTERNAL | EXTERNAL DIMENSION | Ø PISTON | Ø ROD | COUPLER HEIGHT | ROD PROJECTION | DISTANCE FROM ROD AXIS TO THE EXTERNAL | DISTANCE FROM MOUNTING HOLES TO ROD AXIS | DISTANCE BETWEEN THE MOUNTING HOLES CENTERES | THROUGH HOLES FOR ISO 4762 SCREWS | PCD MOUNTING HOLES FOR THE TILT SADDLE | MOUNTING HOLES FOR THE TILT SADDLE | WEIGHT | * Nominal value, see kN for the exact force |

| t* kN | mm | cm² | cm3 | A | D | D1 | E | F | H | K | L | M | U | V | W | S | kg | ||

| 5 | 6 | 7.1 | 4 | CMC5N6 ** | 33 | 59 | 41 | 30 | 24 | 16 | 1 | 20.5 | 22.5 | 28.5 | M5 | – | – | 0.6 | |

| 49.5 | 15 | 11 | 42 | 19 | 0.8 | ||||||||||||||

| 10 | 10 | 15.9 | 16 | CMC10N10 | 43 | 78 | 58 | 45 | 35 | 19 | 1 | 29 | 34 | 37 | M6 | – | – | 1.6 | |

| 111 | |||||||||||||||||||

| 20 | 10 | 28.3 | 28 | CMC20N10 | 52 | 100 | 76 | 60 | 45 | 19 | 1 | 39 | 40 | 50 | M10 | – | – | 2.8 | |

| 198 | |||||||||||||||||||

| 30 | 10 | 44.1 | 44 | CMC30N10 | 59 | 115 | 95 | 75 | 55 | 19 | 1 | 48 | 44 | 52 | M10 | 44 | 2xM5 | 4.2 | |

| 309 | |||||||||||||||||||

| 50 | 15 | 70.9 | 106 | CMC50N15 | 68 | 143 | 120 | 95 | 80 | 19 | 1 | 60 | 54 | 67 | M12 | 65 | 2xM6 | 6.9 | |

| 496 | |||||||||||||||||||

| 75 | 15 | 103.9 | 156 | CMC75N15 | 80 | 166 | 142 | 115 | 100 | 19 | 2 | 71 | 67 | 76 | M12 | 65 | 2xM6 | 12 | |

| 727 | |||||||||||||||||||

| 100 | 15 | 132.7 | 199 | CMC100N15 | 86 | 178 | 160 | 130 | 100 | 20 | 2 | 80 | 75 | 76 | M12 | 65 | 2xM6 | 14.5 | |

| 929 | |||||||||||||||||||

| 150 | 15 | 201 | 302 | CMC150N15 | 100 | 217 | 194 | 160 | 120 | 23 | 2 | 97 | 83 | 117 | M12 | 80 | 2xM6 | 24.5 | |

| 1407 |

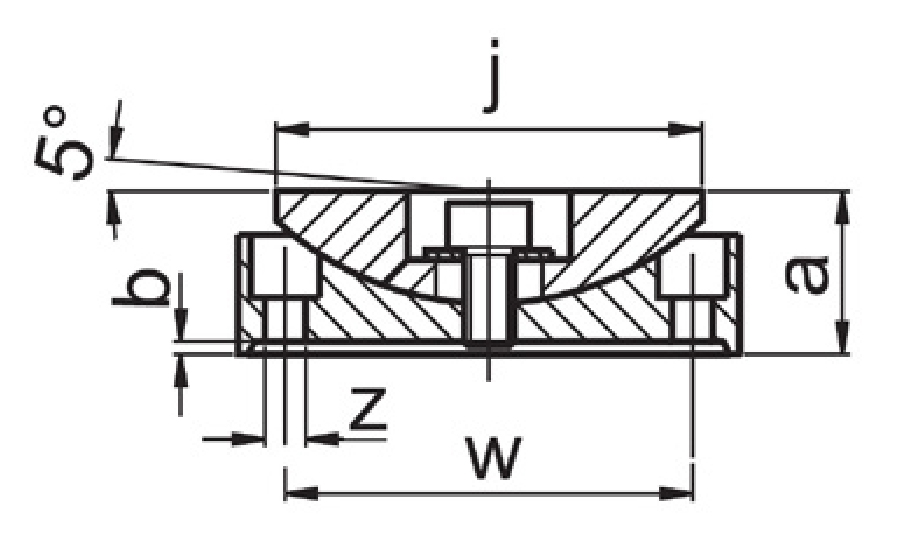

Accessories: ZTT Tilt Saddles

| MODEL | FOR US WITH | a | b | j | z | w | kg |

| ZTT30 | CMC30N10 | 19 | 1 | 53 | 5.5 | 44 | 0.3 |

| ZTT50 | CMC50N15 | 25 | 1 | 68 | 6.5 | 65 | 0.9 |

| ZTT100 | CMC75N15 / CMC100N15 | 34 | 2 | 88 | 1.7 | ||

| ZTT150 | CMC150N15 | 45 | 3 | 118 | 80 | 3.4 |