Description

Operational Areas

Because of their extremely low weight and dimensions, these cylinders are particularly suitable for use in applications where lightness and ease of handling are paramount.

Accessories

- Separate ZTT tilt saddle reduces the effects of possible off-centre loads.

Standard

- Pushing saddle prevents any risk of rod deformation.

The CML cylinders, accompanied by the PN pumps, form a handy, simple, and efficient set.

Selection Chart

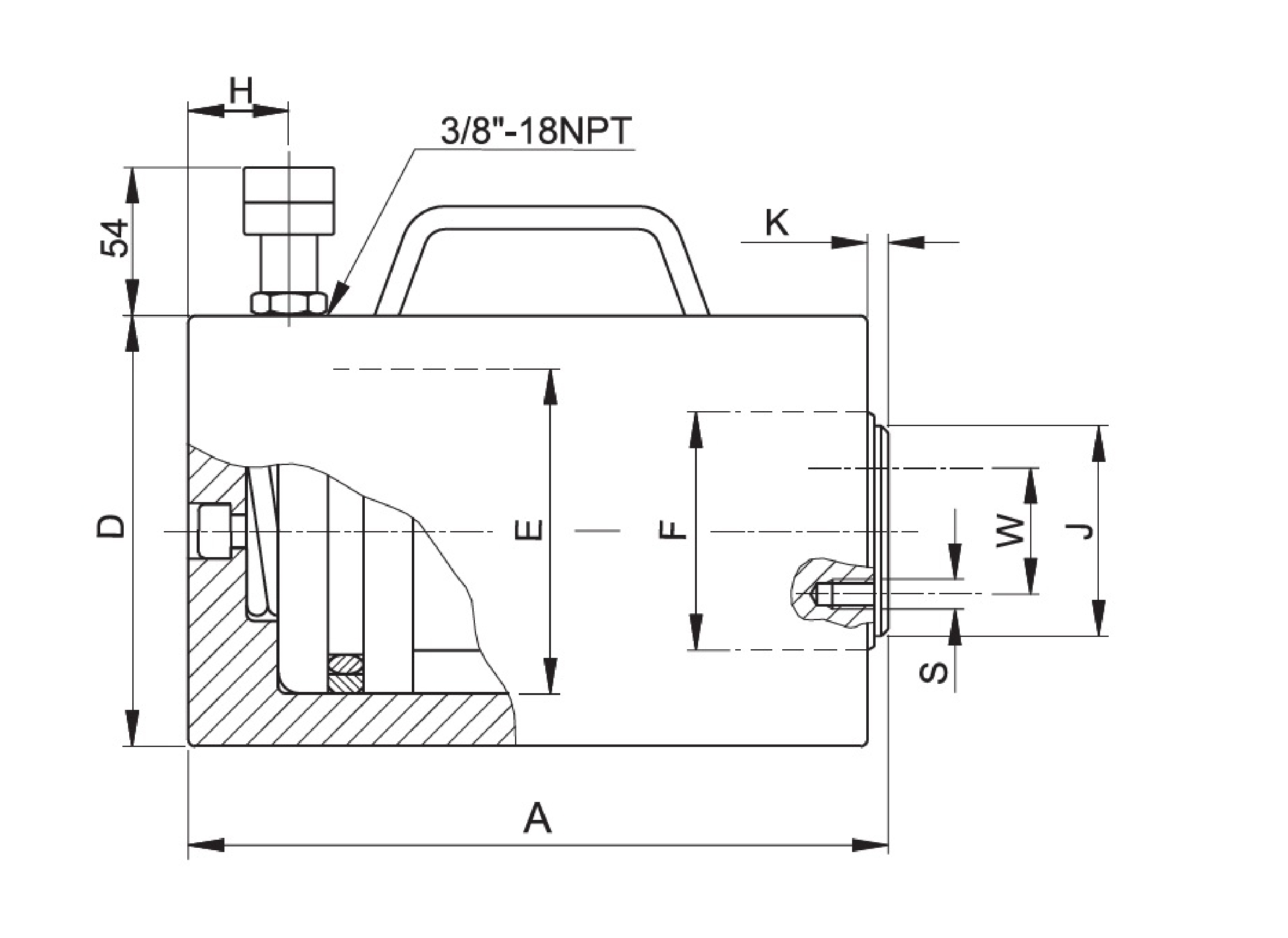

| PUSHING FORCE | STROKE | EFFECTIVE AREA | OIL VOLUME | MODEL | CLOSED HEIGHT | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLER HEIGHT | Ø SADDLE | ROD PROJECTION | PCD MOUNTING HOLES FOR THE TILT SADDLE | MOUNTING HOLES FOR THE TILT SADDLE | WEIGHT | * Nominal value, see kN for the exact force |

| t* kN | mm | cm² | cm3 | A (mm) | D (mm) | E (mm) | F (mm) | H (mm) | J (mm) | K (mm) | V (mm) | S (mm) | kg | ||

|

50 |

50 | 70.9 | 354 | CML50N50 | 158 | 130 | 95 | 80 | 25 | 65 | 4 | 45 | 2xM5 | 95 | |

| 100 | 709 | CML50N100 | 208 | 10.8 | |||||||||||

| 150 | 1063 | CML50N150 | 258 | 12.7 | |||||||||||

|

100 929 |

50 | 132.7 | 664 | CML100N50 | 196 | 178 | 130 | 100 | 25 | 85 | 4 | 65 | 2xM6 | 19.4 | |

| 100 | 1327 | CML100N100 | 246 | 130 | |||||||||||

| 150 | 1991 | CML100N150 | 296 | 25.8 |

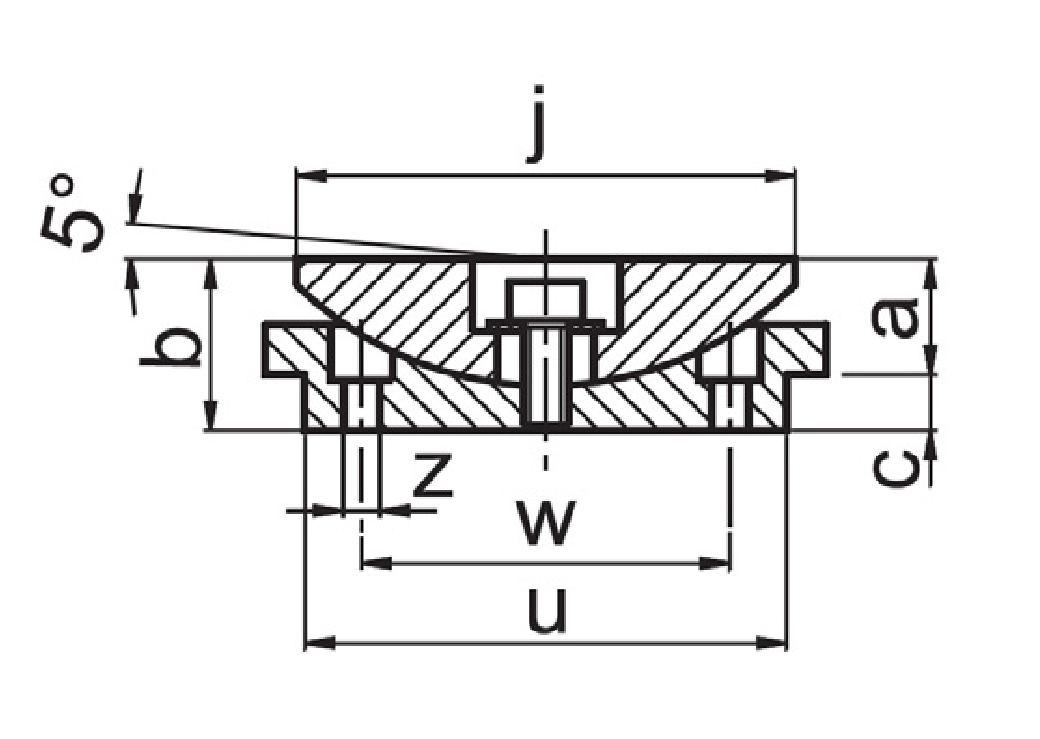

Accessories ZTT Tilt Saddles

| MODEL | FOR USE WITH | a | b | c | j | u | z | w | kg |

| ZTT51 | CML50N # # # | 18 | 26 | 8 | 68 | 65 | 5.5 | 45 | 0.8 |

| ZTT101 | CML100N # # # | 22 | 32 | 10 | 88 | 85 | 6.5 | 65 | 1.6 |