Description

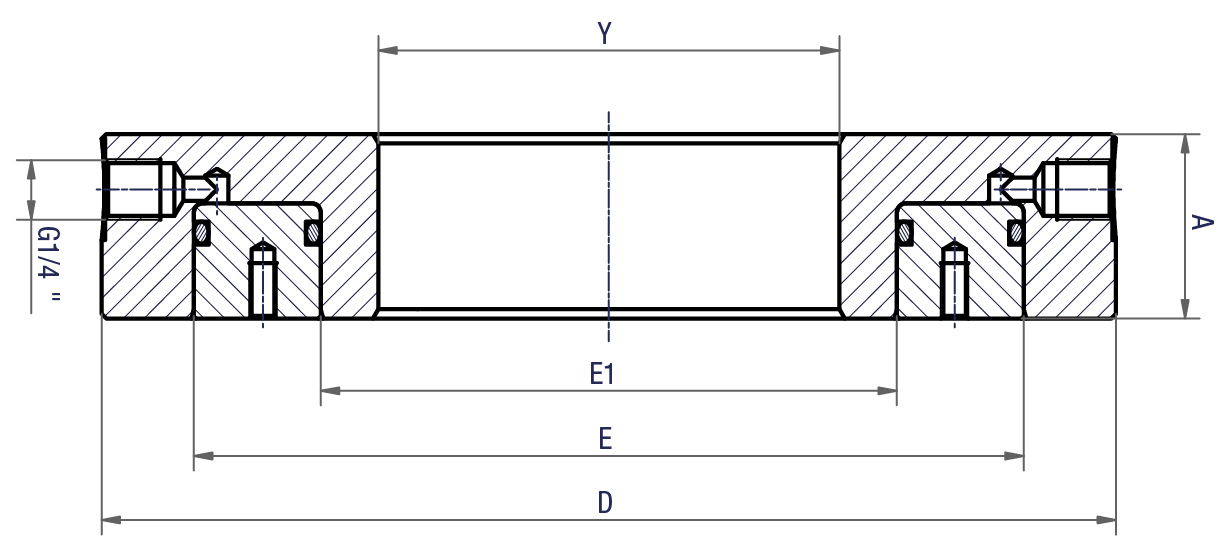

Selection Chart – UHL

| PUSHING FORCE | WORKING PRESSURE | PUSHING AREA | STROKE | OIL VOLUME | MODEL | CLOSED HEIGHT | Ø EXTERNAL | Ø EXTERNAL PISTON | Ø INTERNAL PISTON | Ø THROUGH HOLE | WEIGHT |

| kN | bar | cm2 | mm | cm3 | ALL DIMENSION (mm) | kg | |||||

| A | D | E1 | E2 | Y | |||||||

| 1054 | 800 | 132 | 10 | 132 | UHL100 | 40 | 220 | 180 | 125 | 100 | 9.5 |

| 1100 | 800 | 137 | 10 | 137 | UHL125 | 40 | 245 | 200 | 150 | 125 | 9.8 |

| 1173 | 800 | 147 | 10 | 147 | UHL150 | 40 | 270 | 226 | 180 | 150 | 12.5 |

| 1286 | 800 | 161 | 11 | 177 | UHL175 | 45 | 305 | 250 | 205 | 175 | 17 |

| 1602 | 800 | 200 | 12 | 240 | UHL200 | 50 | 330 | 280 | 230 | 200 | 21 |

| 2070 | 800 | 259 | 12 | 310 | UHL225 | 50 | 365 | 313 | 255 | 225 | 23 |

| 2553 | 800 | 319 | 12 | 383 | UHL250 | 50 | 390 | 345 | 280 | 250 | 28 |

| 3228 | 800 | 403 | 12 | 484 | UHL275 | 50 | 430 | 380 | 305 | 275 | 34 |

| 3511 | 800 | 439 | 13 | 570 | UHL300 | 55 | 470 | 410 | 335 | 300 | 44 |

| 4021 | 800 | 503 | 13 | 653 | UHL325 | 55 | 500 | 440 | 360 | 325 | 49 |

| 4863 | 800 | 608 | 13 | 790 | UHL350 | 55 | 540 | 475 | 385 | 350 | 57 |

| 5781 | 800 | 723 | 13 | 939 | UHL375 | 55 | 575 | 510 | 410 | 375 | 65 |

| 6498 | 800 | 812 | 15 | 1218 | UHL400 | 60 | 620 | 545 | 440 | 400 | 83 |